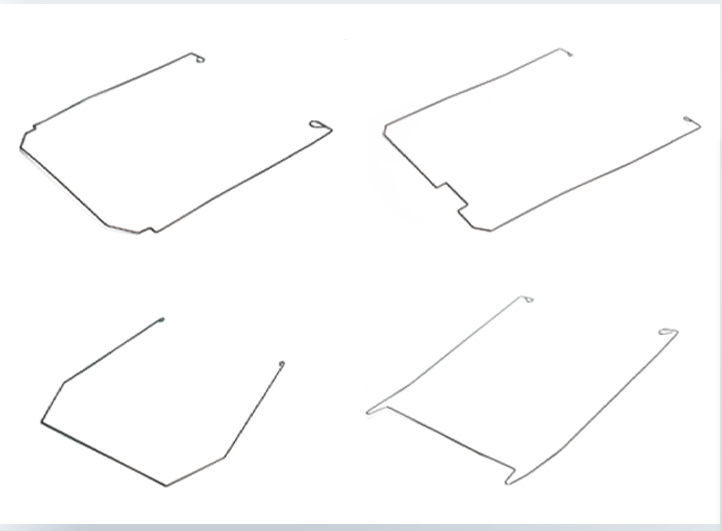

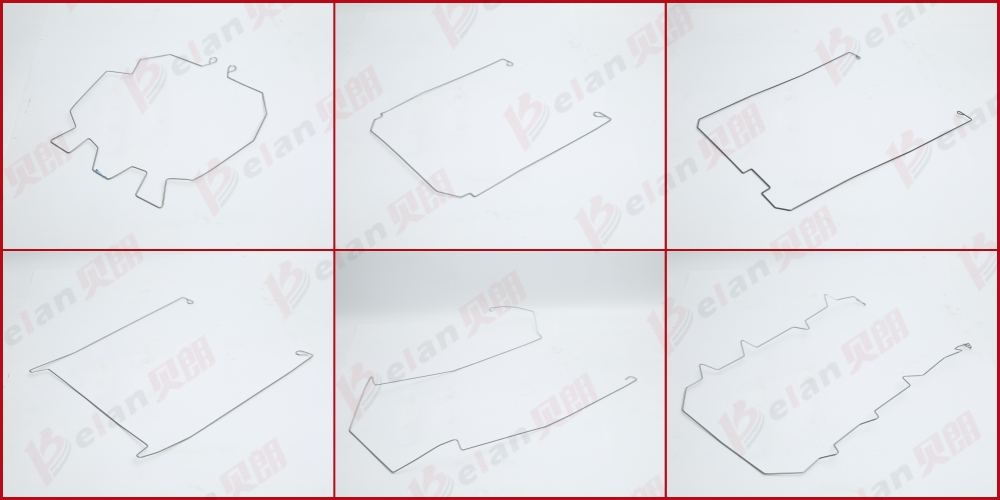

In the world of automotive seating, comfort and safety are built on a hidden foundation — the foam steel wire frame. While invisible beneath layers of foam and upholstery, its bending accuracy directly determines how the seat foam fills, creating the shape, support, and ergonomic fit drivers and passengers experience every day. Precision in wire bending is what ensures that a seat is not only comfortable, but also safe and durable.

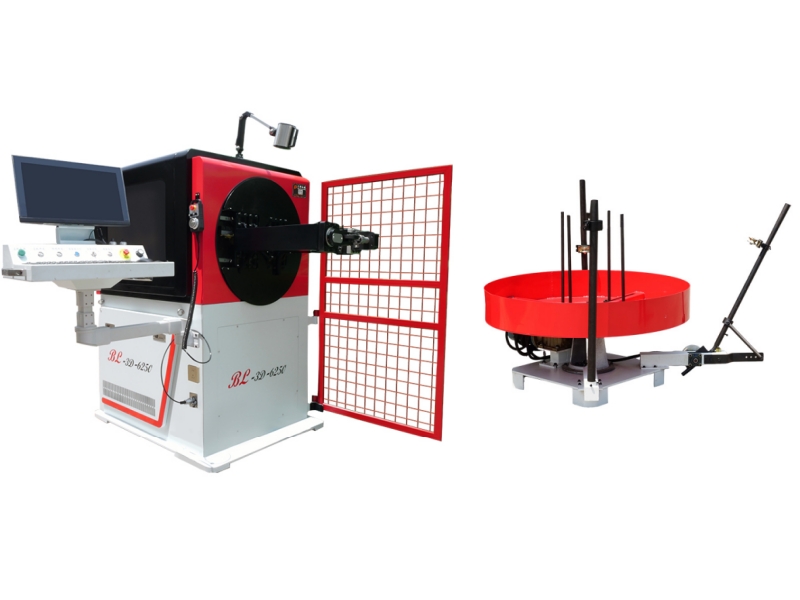

Recognizing the growing demand for precision and efficiency, Belan Automation has developed a dedicated Automotive Foam Steel Wire Bending Machine. Unlike traditional spring machines that were never designed for this specific task, Belan’s specialized equipment offers accuracy, speed, and reliability tailored to the unique challenges of automotive seat production. Since its launch, it has been widely recognized and adopted by leading manufacturers worldwide.

Why Choose a Dedicated Machine Over a Spring Machine?

The automotive foam wire market is large, but most factories have relied on spring machines to handle bending tasks. As general-purpose machines, spring machines struggle with specialized seat frame requirements. Complex structures — such as closed loops for ventilation fans, heating wires, or massage airbag modules — often require secondary processing, leading to inefficiency and inconsistent quality.

Belan’s dedicated Foam Steel Wire Bending Machine changes the game. With advanced forming technology, the machine achieves perfect closed ends in one cycle. Each arc is smooth, tight, and precise, with no gaps or misalignment. This not only enhances product strength and safety but also eliminates rework, significantly improving efficiency — something general-purpose equipment cannot match.

Advanced CNC and Rotary Head Design

The machine features a rotary head design with six-axis full-servo control. During production, the wire remains stationary while the head rotates to achieve 3D bending. This ensures:

Zero wire damage or stress accumulation

Stable, repeatable forming accuracy

Feeding precision of 300 ± 0.1 mm

Bending precision of 90° ± 0.2°

By keeping the wire static, the process minimizes wear and guarantees consistent results across large production runs.

Easier Setup, Faster Training

Unlike spring machines, which require highly skilled technicians for setup, Belan’s dedicated wire bending machine offers an intuitive user interface and simplified programming. Ordinary operators can master the basics in just three days, greatly reducing dependency on experienced technicians.

Production efficiency is typically 20–30% higher than spring machines, giving manufacturers a decisive edge in both productivity and cost savings. Combined with the machine’s competitive pricing, it delivers superior return on investment.

Digital Manufacturing and Industry 4.0 Integration

Modern automotive production is moving toward digitalized factories. Belan’s machine integrates seamlessly with MES systems, uploading all process parameters, output data, and machine status to the cloud in real time. This enables 100% traceability of every production step, ensuring compliance with strict quality standards and supporting long-term process optimization.

By embracing digital connectivity, manufacturers can move closer to Industry 4.0, reducing human error, improving efficiency, and achieving true smart manufacturing.

Driving the Future of Automotive Wire Forming

The shift from general-purpose equipment to dedicated solutions is irreversible. Specialization is replacing generalization, and intelligence is replacing experience-based processes. Belan’s Automotive Foam Steel Wire Bending Machine is a prime example of this trend.

With deep expertise in automotive wire forming equipment, Belan is committed to innovation and continuous improvement. Our mission is clear: help customers reduce costs, improve quality, and increase competitiveness through cutting-edge wire bending technology.

Conclusion

For automotive seating manufacturers, the steel wire frame is more than just a component — it is the invisible backbone of every seat. Belan’s dedicated Foam Steel Wire Bending Machine provides the precision, efficiency, and digital integration needed to meet the demands of modern production.

By choosing Belan, manufacturers gain not only equipment, but also a long-term partner in innovation, efficiency, and success.