Automotive Seat Mesh Forming Machine — The Invisible Yet Strong Support Behind Every Comfortable Ride

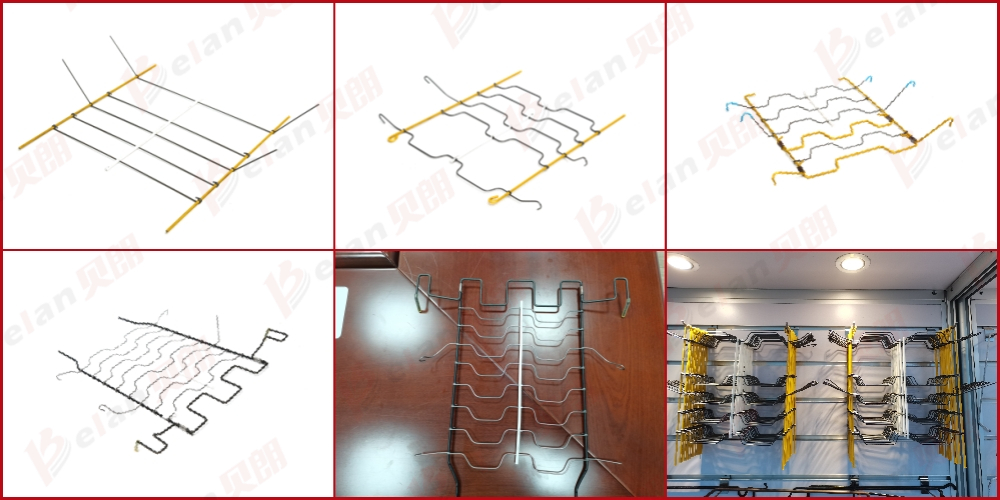

When it comes to automotive seat manufacturing, comfort and safety begin from the inside. Beneath every car seat’s soft surface lies a precisely engineered wire mesh structure — a hidden framework that defines strength, durability, and long-term comfort. Belan Automation proudly introduces its Automotive Seat Mesh Forming Machine, an innovative, fully automatic solution designed for large-scale seat mesh production. This intelligent system provides manufacturers with unmatched accuracy, stability, and productivity in mesh forming and bending.

Reliable Support, Precision Engineering

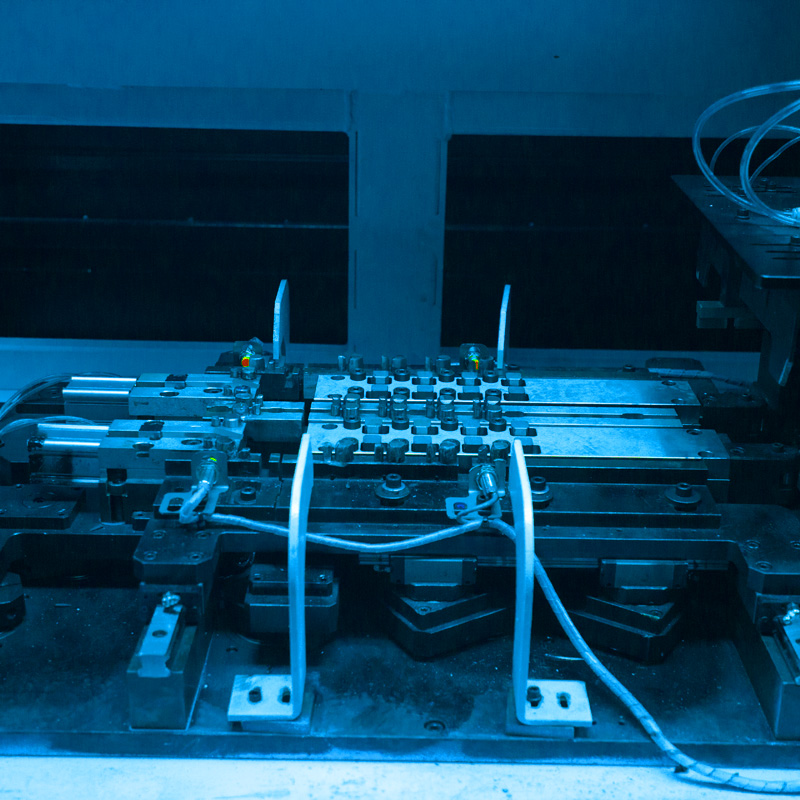

The seat mesh forming machine developed by Belan G Automation offers a stable and reliable performance that meets the high standards of modern automotive production lines. Its dual-display computer control system and multi-channel bus communication ensure intuitive operation and consistent accuracy. Even during high-volume production, the wire frame dimensions remain perfectly stable, guaranteeing uniformity across every batch.

Multi-Axis Control for Complex Mesh Structures

Equipped with 35 to 58 servo axes, the system achieves synchronized bending of complex spatial curves. This advanced control prevents wire torsion or deformation during forming, ensuring precise shaping even in challenging designs. Each workstation can bend multiple angles simultaneously, and all parameters can be adjusted freely according to product specifications. This flexibility allows manufacturers to switch seamlessly between different seat models or mesh patterns with minimal setup time.

Versatile Forming Capabilities

The Belan seat mesh machine can handle both steel wire and plastic-coated steel wire, weaving them into strong and resilient mesh structures. By simply changing the mold, operators can produce various mesh types automatically — from small-scale seat back frames to large ergonomic seat bases — making it an ideal solution for diversified automotive seating applications.

Smart Monitoring and Safety Design

To ensure safe and efficient operation, the entire forming and weaving process is equipped with video monitoring for real-time production control. The machine body is fully enclosed with sheet metal protection and features three safety rolling doors for operator security. Remote operation and monitoring are also available, providing convenience and control at every stage.

Customizable Feeding System

Depending on product size and material type, the machine can be configured with 5 to 7 automatic wire feeding racks, allowing continuous production without manual intervention. This multi-wire feeding capability further enhances efficiency and supports large-scale, uninterrupted manufacturing.

Intelligent Closed-Loop System

Belan’s independently developed “Weaving–Detection–Correction” closed-loop system is at the heart of the machine’s precision. This unique innovation automatically detects and corrects any deviation in the wire path or mesh pattern, ensuring perfect forming results every time. Combined with Internet-based remote maintenance, the system enables quick diagnostics and technical support — reducing downtime and maintenance costs significantly.

High Cost Performance, Long-Term Value

Compared with traditional mesh forming solutions, the Belan machine delivers higher precision, faster forming speed, and greater adaptability — all while maintaining an excellent cost-performance ratio. Whether you are producing seat frames for passenger cars, commercial vehicles, or luxury models, this equipment provides the reliability and productivity your factory needs to stay ahead in the automotive supply chain.

Why Choose Belan Automation

Over a decade of R&D experience in CNC wire bending and mesh forming

Proven expertise in automotive, furniture, and industrial wire applications

Global service network and remote maintenance support

Customizable solutions for different wire diameters and mesh geometries

Trusted by manufacturers worldwide for precision and durability

Empowering the Future of Automotive Seating

The Automotive Seat Mesh Forming Machine by Belan Automation represents more than just advanced manufacturing — it’s the invisible yet solid support behind every comfortable seat. As vehicles evolve toward higher comfort and safety standards, our technology continues to redefine what’s possible in automated wire forming and mesh weaving. Upgrade your production line with Belan’s intelligent forming solutions — and experience the perfect balance of strength, precision, and innovation.