Selecting the right copper and aluminum busbar bending machine is essential for ensuring bending accuracy, production efficiency, and compatibility with different material specifications. BELAN’s CNC busbar bending series—covering multiple models from small-size flexible bending to heavy-duty wide-busbar applications—provides manufacturers with precise control over width, thickness, torque, and bending speed.

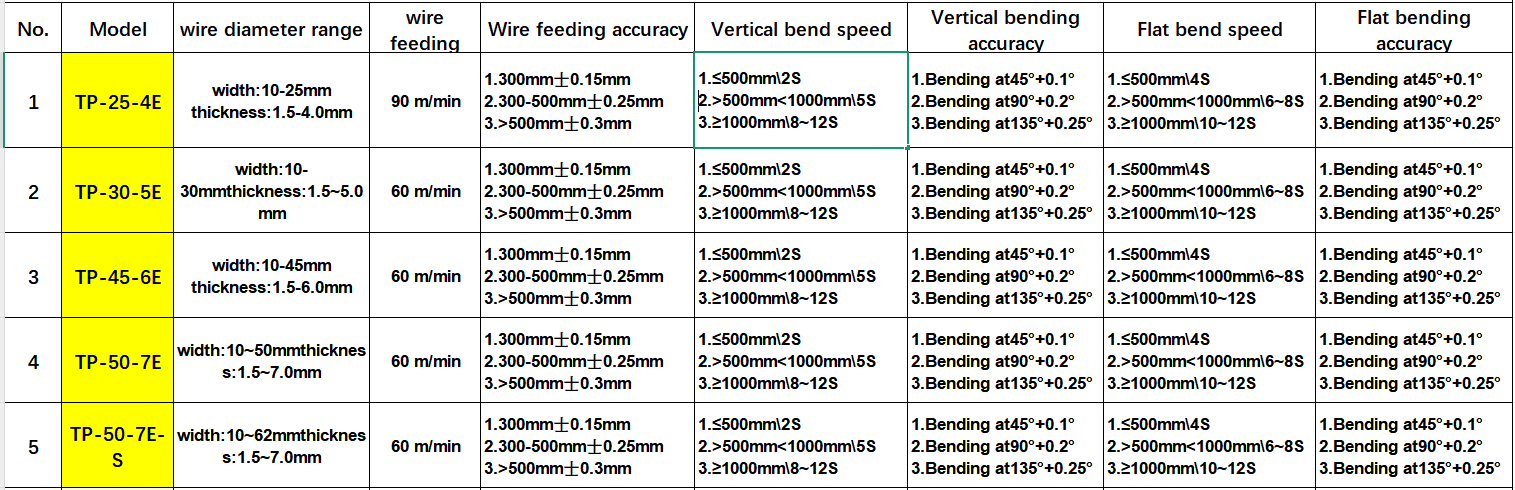

The following comparison table outlines the key bending capacities of five BELAN models, helping engineers quickly evaluate the most suitable equipment for electrical cabinet production, power distribution systems, EV charging infrastructure, and industrial automation.

By understanding the bending capacity, material range, precision, and speed differences among BELAN’s five busbar bending machine models, manufacturers can make accurate equipment selections that reduce production errors, improve workflow efficiency, and ensure long-term reliability in copper and aluminum busbar processing.

Whether for compact electrical components or high-power distribution systems, BELAN delivers stable performance and consistent bending quality across all models—making it a trusted choice for modern busbar manufacturing.