In the automotive parts industry, the double-head wire forming machine plays a crucial role in producing rear seat wires, dual serpentine springs, and asymmetrical long-rod steel components. For many years, this market was dominated by Korean manufacturers, leaving global customers constrained by high prices and limited service flexibility.

Today, with the rapid progress of China’s smart manufacturing, domestic equipment is emerging as a strong competitor. Belan Automation Equipment Co., Ltd. has developed its own double-head wire forming machine, offering automotive suppliers worldwide a new and competitive alternative.

Customer-Oriented R&D

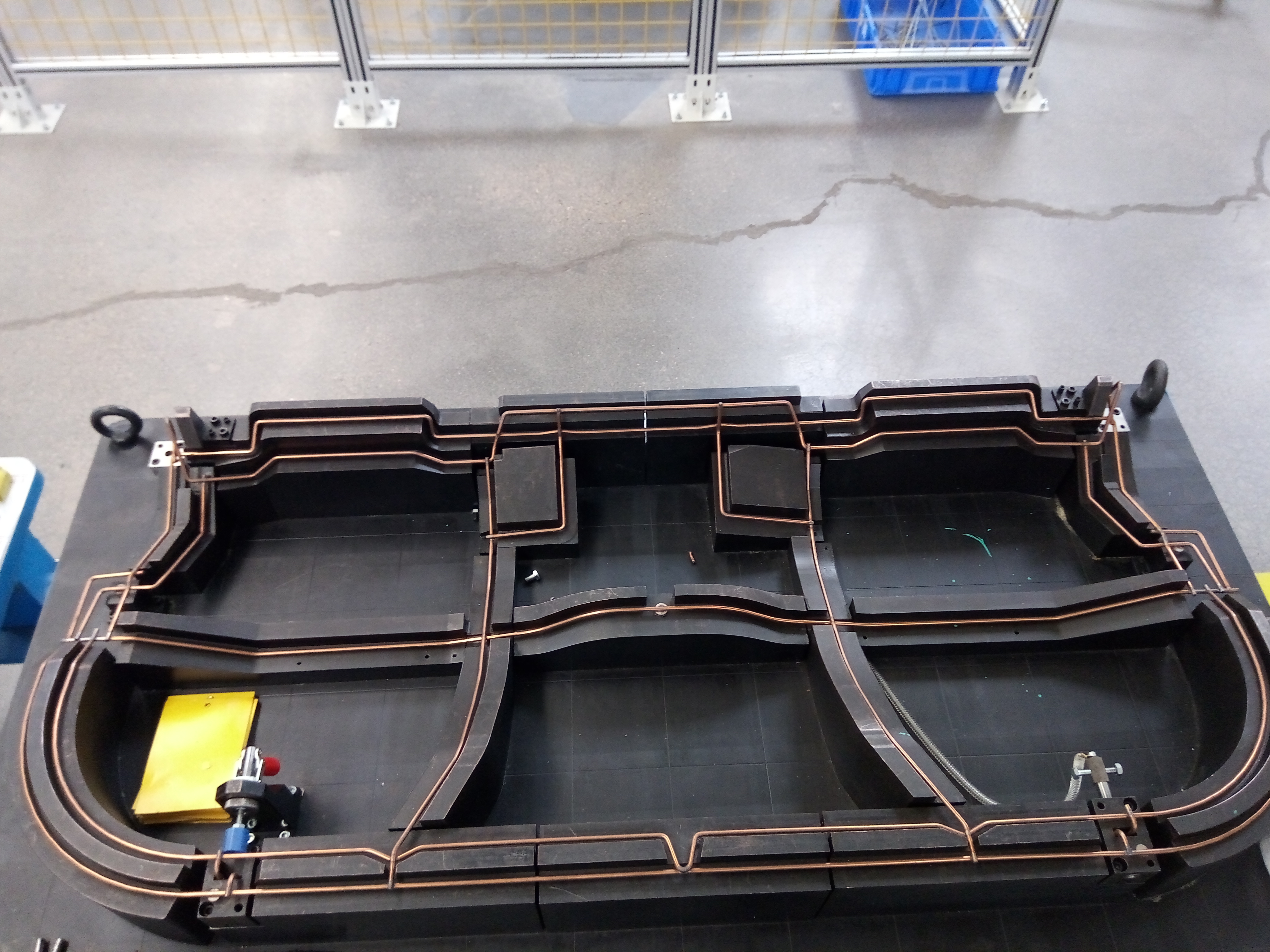

Belan’s R&D team has spent years visiting customer plants, collecting insights from leading automotive seating and component manufacturers. With over a decade of technical expertise in CNC wire forming machines, Belan successfully launched a domestic double-head forming solution. Since entering the market, the equipment has passed rigorous on-site tests—often running side by side with Korean machines in the same workshops. Customers have repeatedly chosen Belan through continuous reorders, validating the efficiency and stability of the product.

Key Advantages of the Belan Double-Head Wire Forming Machine

Dual inner and outer coiling: easily switch between different R angles.

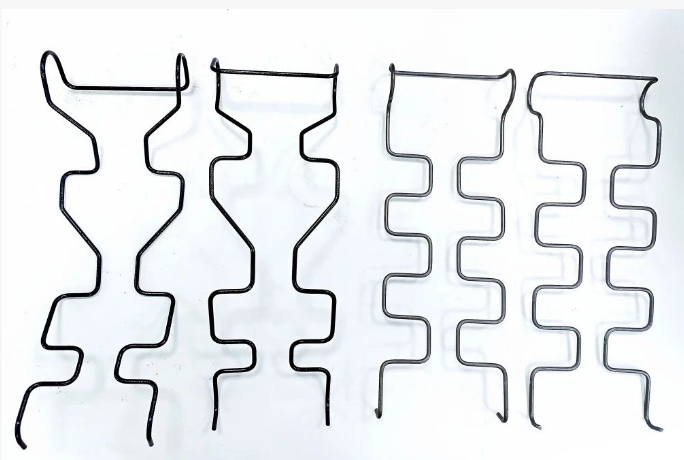

Shortest head distance of 120 mm: enabling high-difficulty products such as dual serpentine springs.

Precision feeding with encoder system: achieving accuracy of 300 ± 0.1 mm.

Four sets of straightening rollers: ensuring superior wire straightness.

Dual-motor clamping system: providing stable clamping and rotating control.

These innovations directly address long-standing industry pain points, enabling automotive manufacturers to achieve higher productivity and reduced defect rates.

Proven by Leading Automotive Suppliers

Thanks to customer trust and support, Belan’s double-head wire forming machines are now successfully serving major companies including FAW Fuwei Andotuo (Changchun), Spring City Xianghe, Chongqing Jinjia, Shanghai Suzhen, Anhui Zhongteng, and Zhejiang Jiulong, among others. Beyond China, the machines are also exported to Turkey, India, and Malaysia, reflecting strong international recognition.

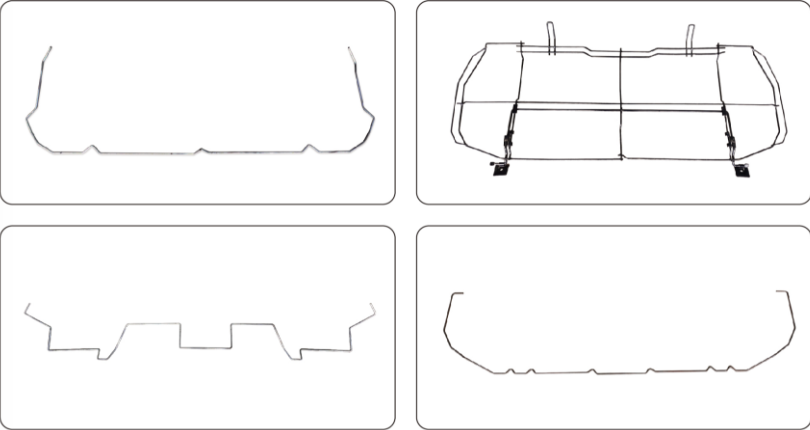

The machine is particularly well-suited for rear seat wire frames, dual serpentine springs, and long-rod steel wire products, offering significant advantages in speed and stability compared with single-head equipment.

Driving the Future of Smart Manufacturing

Belan believes that industrial progress and smart manufacturing will make the world a better place. In this new era of China’s advanced manufacturing, Belan is committed to working with global customers, delivering high-end CNC wire forming machines, and shaping a new landscape for automotive component production.