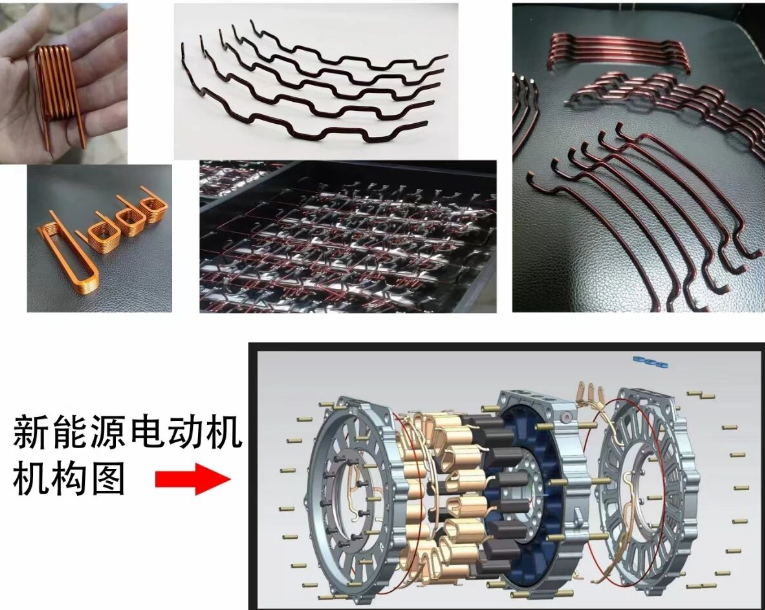

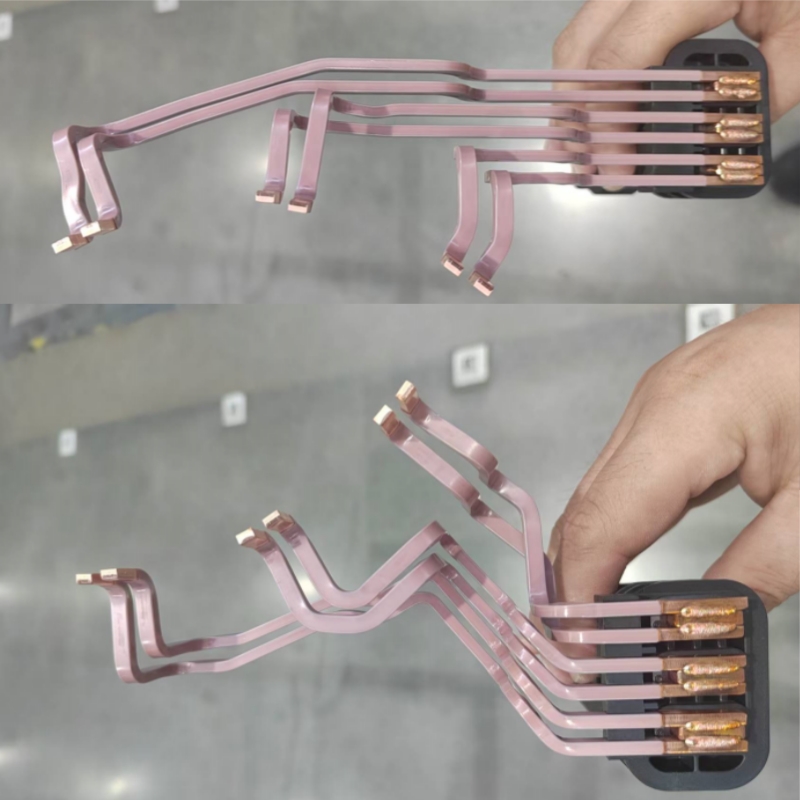

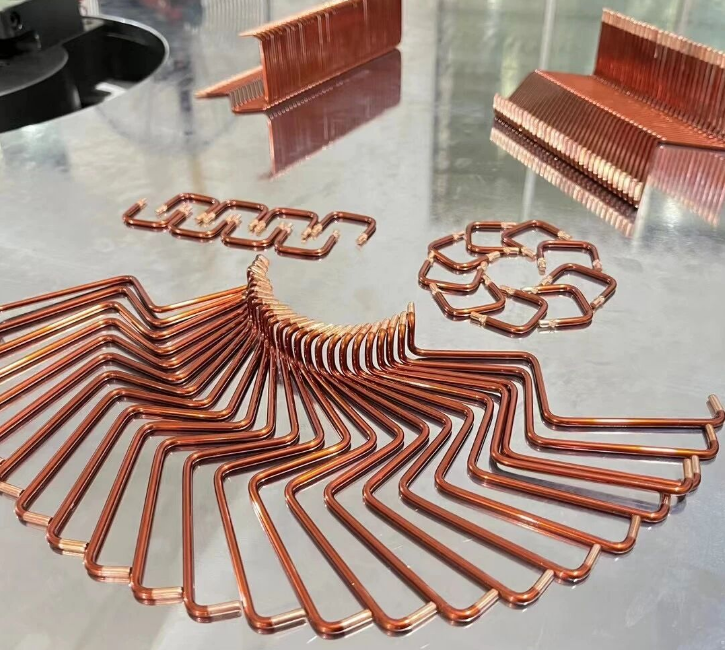

In modern industrial manufacturing, enameled copper wire bending has become a critical process in industries such as electric motors, transformers, and new energy automotive components. From motor jumper wires and stator leads to busbar connection wires, the forming quality of enameled copper wires directly determines the performance and reliability of the end product.

Traditional bending methods often face three major problems: insufficient precision, damage to insulation coatings, and low production efficiency. To address these pain points, Belan Automation has introduced a new generation of enameled copper wire bending machine, delivering three innovative solutions that are reshaping the industry.

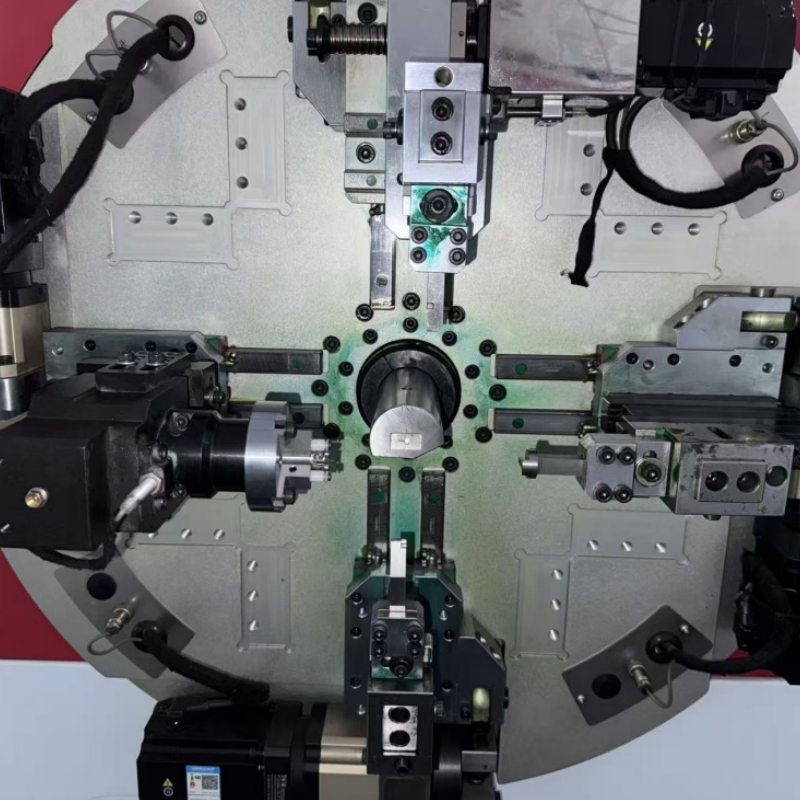

First Solution: “Wire Fixed, Table Rotating” – Eliminating Insulation Damage

The machine adopts an innovative rotary forming structure where the wire itself does not twist during bending. Instead, the forming table rotates, avoiding torsional stress that often leads to invisible enamel coating damage. This structural design ensures higher consistency, reliability, and long-term stability in production.

Second Solution: Dedicated Tooling and Precision Stripping – Enhancing Accuracy

For enameled wire applications, the machine is equipped with custom forming tools designed to minimize pressure marks or scratches on the wire’s insulation surface. At the same time, an independent stripping system allows precise control of stripping depth and length. This guarantees that every bending and stripping operation is accurate to the smallest detail, preserving insulation integrity while improving product precision.

Third Solution: Automation and MES Connectivity – Boosting Efficiency and Smart Management

Beyond mechanical performance, the enameled copper wire bending machine integrates features for automation and digital factory management:

Built-in dust collection and waste storage keep the work environment clean.

Full MES system integration enables cloud-based process parameter management and 100% traceable production data.

Together, these features significantly improve production efficiency, reduce downtime, and create a foundation for intelligent manufacturing.

Technical Highlights

Feeding precision: 300 ± 0.1 mm

Bending angle accuracy: 90° ± 0.2°

Program storage: Over 2000 sets

Multilingual interface: Seamless global operation

These technical parameters demonstrate how the machine balances high performance with user-friendly operation, meeting the demands of advanced manufacturing environments.

Trusted by Leading Global Customers

This enameled copper wire bending machine has already been adopted by multiple global manufacturers, including Schaeffler, a top-tier automotive parts supplier. Their choice reflects trust not only in the equipment’s stability and performance but also in its ability to improve yield rates and ensure consistent product quality.

A Complete Solution for Modern Manufacturing

Belan Automation offers more than just a machine—it provides a complete solution for quality assurance, process optimization, and Industry 4.0 transformation. For manufacturers struggling with enamel insulation damage, low efficiency, or bending inaccuracies, this machine delivers proven answers validated by leading industry players.