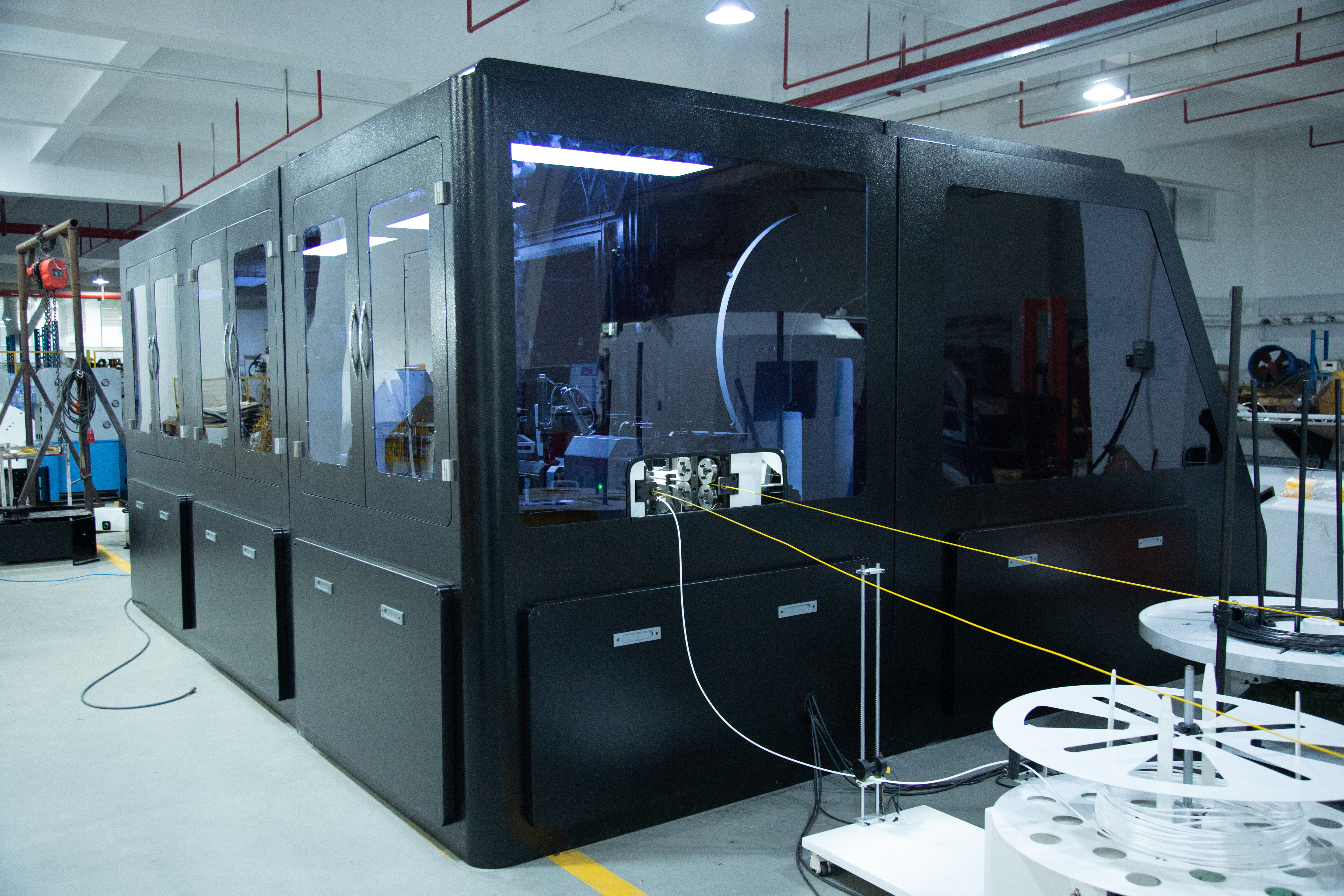

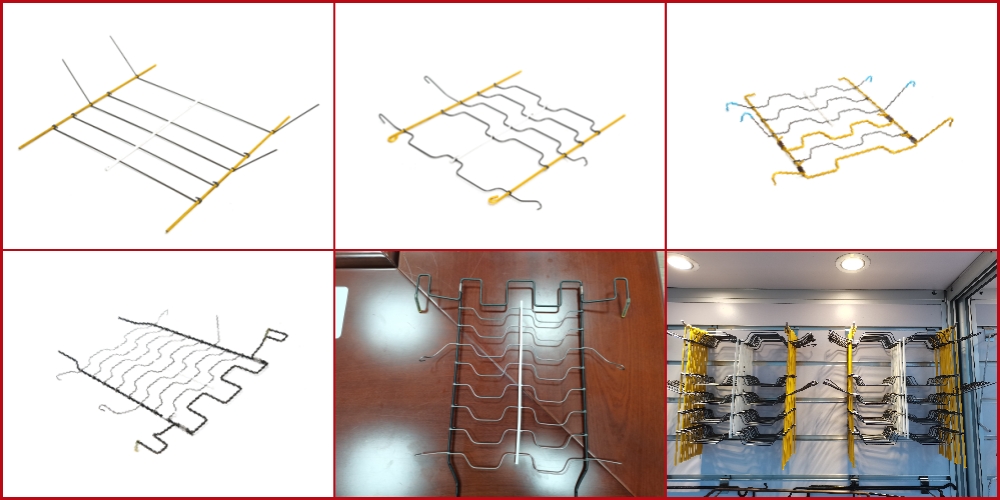

The car seat backrest mesh forming machine is a fully automated intelligent equipment designed specifically for the production of car seat support brackets. It integrates multiple core processes such as wire threading, bending, rubber tube fitting, stamping bending, and secondary bending, achieving seamless production from raw materials to finished products. With modular design, flexible configuration, and intelligent control, this device can accurately match different production needs, helping customers create high-precision and highly consistent seat grid support brackets, greatly improving production efficiency and product quality.

Full process automation, doubling efficiency

Breaking through the traditional manual step-by-step operation mode, through the collaboration of intelligent robotic arms, high-precision servo systems, and visual inspection technology, the full process unmanned operation of steel wire threading, rubber tube positioning, multi angle bending and other processes is achieved. The production cycle is increased by more than 50%, and labor costs are reduced by 70%.

Precise process integration, excellent quality

By using high rigidity molds and dynamic compensation algorithms, the bending angle error of the steel wire is ensured to be ≤ ± 0.5 °, and the position accuracy of the rubber sleeve reaches ± 0.1mm, completely eliminating dimensional deviations caused by manual operations; The linkage optimization of stamping bending and secondary bending process perfectly adapts to complex curved structures, and improves the durability of finished products by 30%.

Modular customization, flexible adaptation to requirements

Supporting customized design of workstation quantity, process combination, and mold specifications, it can cover diverse seat bracket production needs from economical to high-end models. The changeover time is shortened to within 30 minutes, helping customers quickly respond to market changes.

Application scenarios

Automotive seat manufacturing: suitable for mass production of seat back support brackets for passenger cars, commercial vehicles, and special vehicles.

Service guarantee

We provide full cycle services from equipment selection, process debugging to personnel training, promising 24-hour rapid response and lifelong technical support to ensure worry free production for customers. The equipment comes standard with energy-saving modules, which reduce energy consumption by 15% compared to similar products and help promote green and intelligent manufacturing.

Choose us and you will receive:

✅ One set of equipment replaces multiple dispersed processes, compressing the production cycle;

✅ Stable and consistent product quality enhances brand competitiveness;

✅ Scalable smart factory interface lays the foundation for digital transformation.

Consult now and customize your exclusive automation solution!