Copper and aluminum busbars are essential in electrical and energy industries. Their precision processing relies heavily on the reliability of CNC busbar bending machines. To ensure long-term efficiency and performance, regular maintenance is a must.

This guide covers the standard maintenance procedures for Belan CNC copper and aluminum busbar bending machines, helping users extend equipment life and improve productivity.

I. Lubrication Guidelines

Only use lubricants specified in the operation manual. Mixing different brands or using degraded, contaminated, or corrosive lubricants is strictly prohibited.

Before replacing lubricant, remove old oil thoroughly and clean mechanical parts with gasoline or diesel. Only filtered oil that meets quality standards may be reused.

For new machines, the lubricant must be replaced within 15 days of operation to prevent early-stage impurities from damaging bearings or gear components.

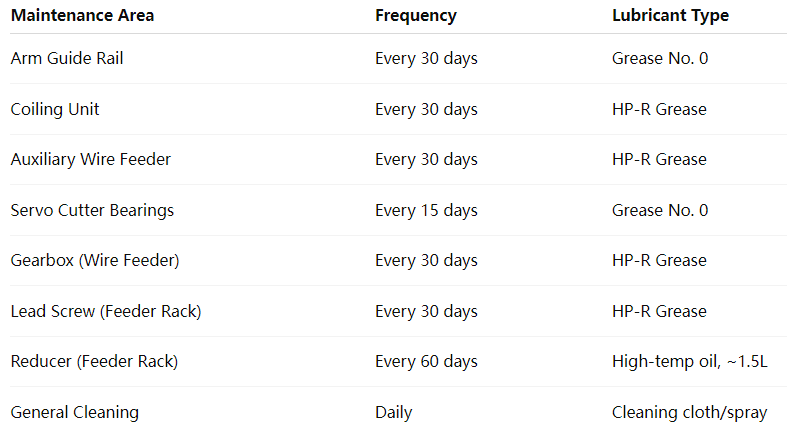

II. Key Maintenance Points and Intervals

III. Why Is Maintenance So Important?

Copper and aluminum are highly conductive and sensitive to processing accuracy. Without proper maintenance, even minor deviations can cause serious electrical performance issues. Preventive care helps reduce machine downtime, improve reliability, and enhance your automated busbar processing workflow.

IV. Conclusion

From photovoltaic panels and energy storage to electrical cabinets and EV systems, CNC copper and aluminum bending machines play a crucial role in the production chain. A smart maintenance routine helps maximize machine performance and supports sustainable, high-efficiency manufacturing.

Need support or technical documents? Contact the Belan team today.