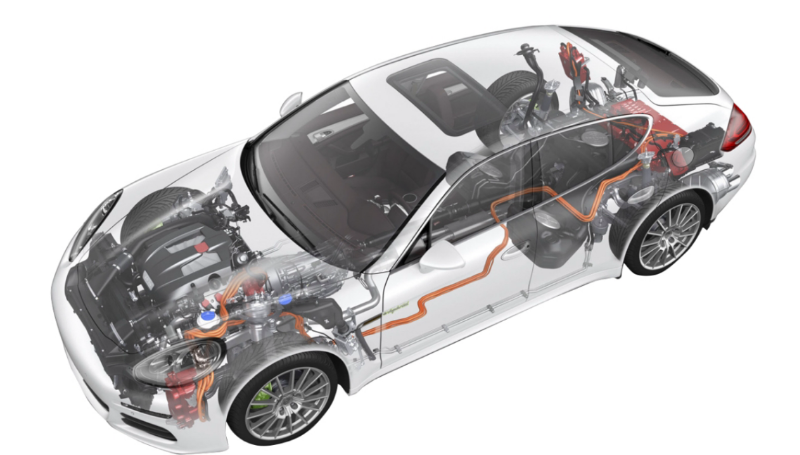

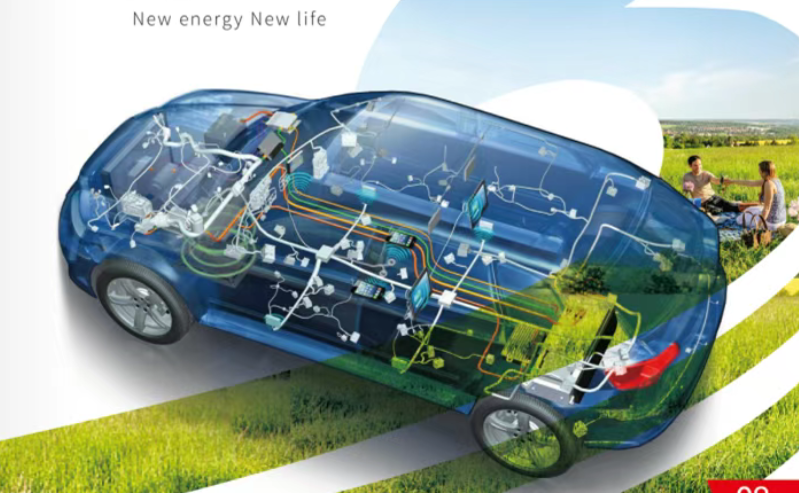

With the rapid rise of the new energy vehicle (NEV) industry, automakers are placing higher demands on conductive components. In high-voltage circuits, the critical conductive parts connecting the charging socket to the battery pack are typically copper and aluminum busbars.

These busbars must undergo multiple bends and turns inside the vehicle. Achieving efficient and precise copper busbar bending and aluminum busbar bending has therefore become a significant challenge for many EV component manufacturers.

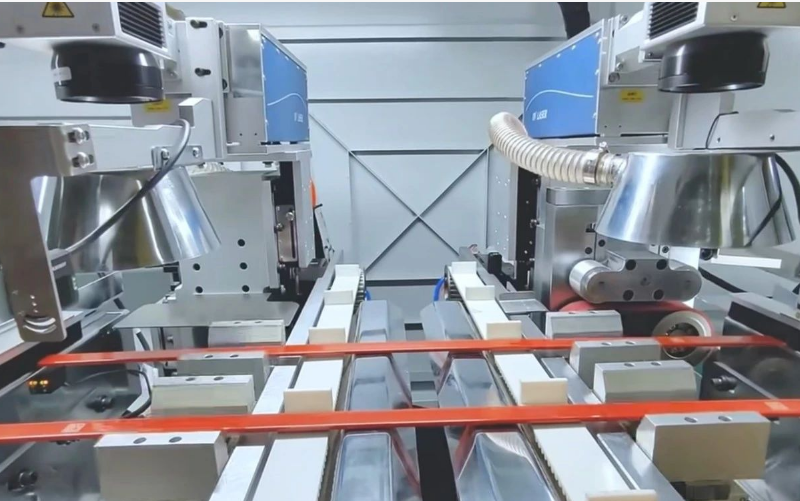

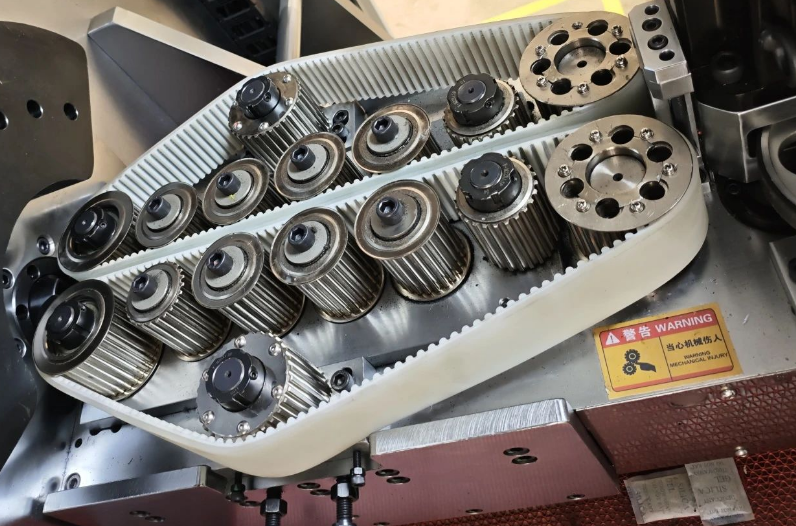

Belan Automation Equipment Co., Ltd. has launched an advanced busbar bending machine that is transforming production methods in this field. With its patented track feeding structure and multiple outstanding features, the Belan busbar bending machine sets new standards in EV busbar processing.

Key Innovation Highlights of Belan Busbar Bending Machine

Track Feeding, Precision & Efficiency: Patented track feeding grips the insulated surface, prevents damage, and ensures high feeding accuracy. Quick stroke adjustment reduces downtime, improving busbar processing efficiency.

Auxiliary Feeding System: Single operator can handle and set up 300² busbars, increasing productivity.

Easy Programming & Quick Adjustment: Manual programming shortens trial cycles and accelerates product changeovers.

Memory-Scale Straightening: Scale with memory function allows fast switching between busbar specifications.

Smart Connectivity: Direct integration with MES systems, enabling cloud data sharing and 100% production traceability.

High Precision Performance: Feeding accuracy of 300±0.1mm; bending angle accuracy within 90°±0.2.

Multi-Function Integration: Supports flat, vertical, torsion bends, punching, chamfering, and double coiling—meeting complex busbar manufacturing needs.

Trusted by Leading EV Manufacturers

Since its market launch, Belan’s busbar bending machines have been recognized by global leaders such as Aptiv, Leoni, Dekko, and AVIC Optoelectronics. The innovative track feeding design sets new benchmarks for quality, reliability, and efficiency in EV busbar manufacturing.

Shaping the Future of Electric Mobility

As the electric vehicle industry continues to expand, demand for higher precision, efficiency, and reliability in busbar processing will keep rising. Belan Automation is committed to delivering advanced CNC busbar machines that empower automakers and suppliers, strengthening production capacity and accelerating the shift to greener, more efficient electric mobility.