🚗 1. Precision and speed - transformation of wiper arm production

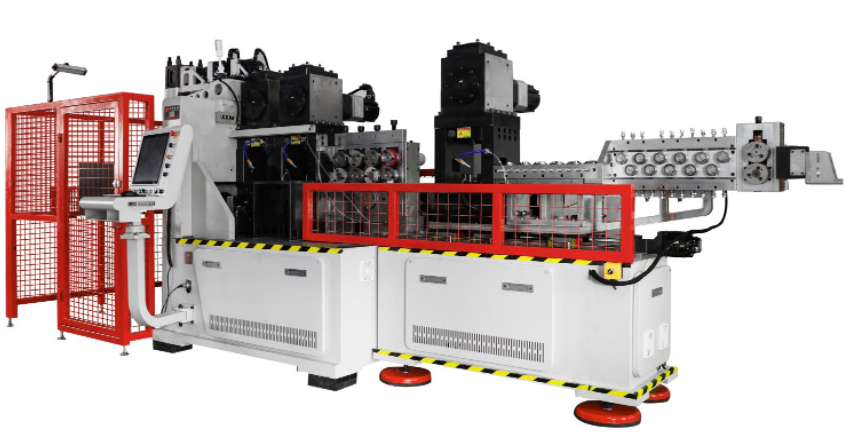

The traditional production method of wiper arms relies heavily on manual operation, which often leads to unstable quality and limited output. Belan's forming machine has completely changed this situation with the following advantages:

High-precision servo motor drive system

Multi-station continuous stamping technology

Intelligent real-time mold correction system

The production efficiency of each automotive wiper arm molding is increased by 30%. More importantly, the tolerance control of ±0.02 mm ensures consistent quality and minimizes rework.

🌱 2. Energy-saving design - born for sustainable manufacturing

In response to global carbon reduction targets, B. Braun has carefully designed this molding machine to reduce power consumption and waste heat:

Energy consumption is reduced by 40% through optimized hydraulic motor coordination

Built-in waste heat recovery system, which can use heat energy for mold preheating or equipment heating

Each production line can save more than 50,000 yen per year and reduce carbon emissions equivalent to planting 300 trees

This is undoubtedly an ideal choice for environmentally conscious manufacturers seeking green factory solutions.

📱 3. Smarter operation - welcome to Industry 4.0

Belan automotive wiper arm molding machine is equipped with an industrial IoT module for seamless data collection and predictive maintenance:

Real-time data upload to the cloud

Mobile application monitors production and energy consumption curves

Failure warning 72 hours in advance

Customer feedback shows that the machine reduces the need for on-site operators, and only one person can complete the work that used to require three people, thereby reducing labor costs by half.

🛡 4. Built-in quality control - durability from the source

Product quality is not only monitored, but also carefully designed from scratch:

Aerospace-grade alloy molds with a service life of more than 2 million times

Integrated six-axis robotic arm for scratch-free automatic loading and unloading

Seven-level quality tests, including laser measurement and salt spray testing

The equipment can withstand extreme weather conditions from -40℃ to 80℃, ensuring that each wiper arm can operate reliably on the road.

A trusted partner for global automakers

Belan's automotive forming machines have been deployed in more than 200 factories around the world, and many equipment have been running stably for more than 50,000 hours. Our customers range from electric vehicle innovators to joint venture automotive giants, and they all value our commitment to performance, reliability and innovation.

If you are looking for ways to optimize automotive wiper arm production, reduce downtime and lower operating costs, B. Braun automotive wiper arm forming machines are your ideal choice.

📞 Contact us today to learn how our cutting-edge equipment can boost your productivity and help you stay ahead in the competitive automotive industry.

🌐 Visit our website for more information: www.wirebendingcnc.com

📧 Email: belan@wirebendingcnc.com

Car wiper arm forming machine video