parameter

| Type | BL-3D-5600Parameter | |

| Applicable Wire Dia. | Soft material Φ:2.5-6.0mm Hard material Φ:2.5-4.0mm | |

| Bending stroke | 600mm | |

| Number of control Axis | 6 Axis | |

| Total power | 8.2KW | |

| Power Of Roating arm Motor | 2.9KW | |

| Power of wire feeding motor | 2.9KW | |

| Folding motor power | 1.0KW | |

| Lifting motor power | 0.4KW | |

| Power Of wire cutting Motor | 1.0KW | |

| Maximum wire feeding speed | 90M/min | |

| Wire feeding accuracy | 300mm±0.1mm | |

| Angle accuracy | 90°±0.2° | |

| Input Power | 380V/50Hz/3Ph | |

| Weight | 1800KG | |

| Machine Size(L*W*H) | 3000×1900×1900mm | |

| Automatic feeder | Maximum load Weight: | 500KG |

| Diameter of Round Tray | φ1300mm | |

| Input Power | 1.5KW | |

| Weight | 450Kg | |

| Size (L*W*H) | 2000*1550*1250mm | |

Description of wire bending machine

High Precision: 5 axis high precision CNC automatic iron wire bending machines are known for their high level of precision in producing complex wire forms. They can consistently create intricate shapes with tight tolerances, ensuring that each product meets exact specifications.

Versatility: These machines can handle a wide range of wire diameters and materials, including steel, aluminum, copper, and more. This versatility makes them suitable for a diverse array of applications across different industries.

High Production Speeds: Rotary wire bending machines are capable of high-speed production, which leads to increased throughput and efficiency. This is particularly important in industries where large quantities of wire forms are needed.

Reduced Setup Time: Modern rotary wire bending machines often come equipped with advanced computer numerical control (CNC) systems. These systems allow for quick and easy programming and setup, reducing the time it takes to switch between different wire-forming jobs.

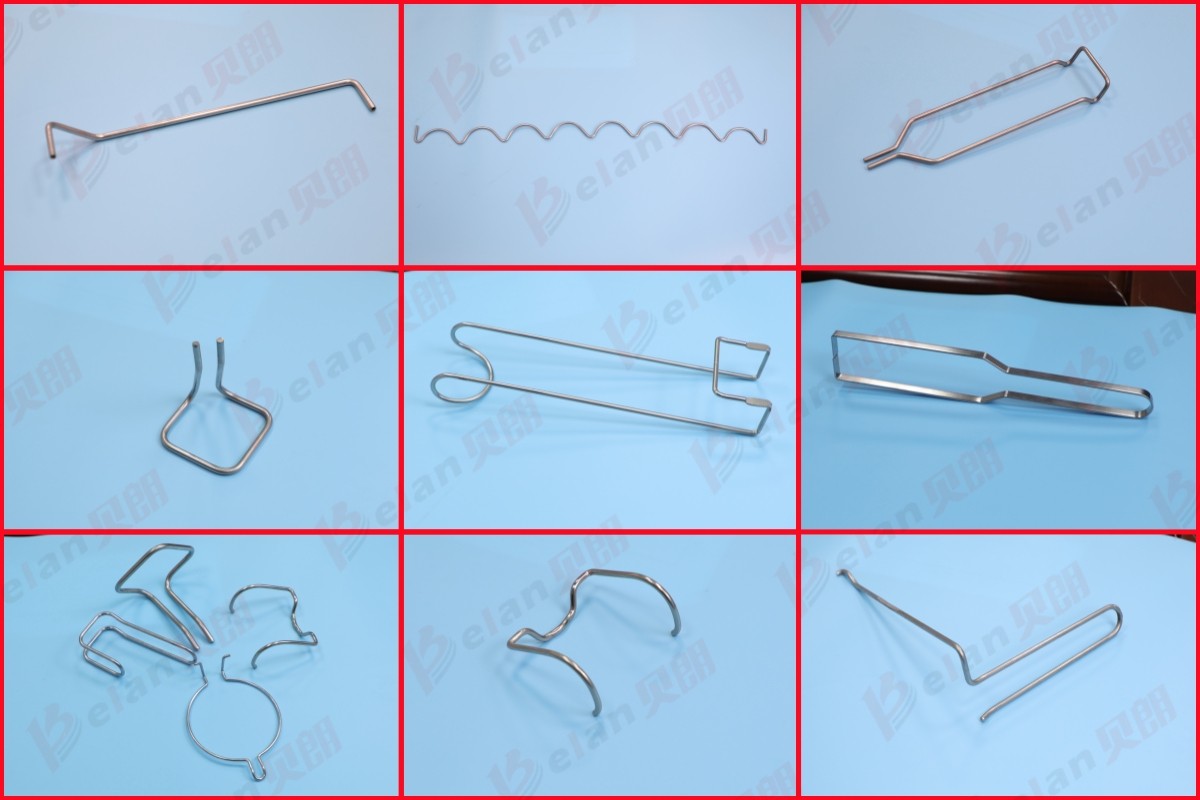

Sample image display