Specification parameters

| Type | BL-3D-81200 Parameter | |

| Applicable Wire Dia. | Soft material Φ:4.0-12.0mm Hard material Φ:4.0-10.0mm | |

| Bending stroke | 850mm | |

| Number of control Axis | 8 Axis | |

| Total power | 29KW | |

| Power Of wire turning Motor | 7.5KW | |

| Power of wire feeding motor | 4.5KW | |

| Power Of Angle control Motor | 2.0KW | |

| Inner/outer angle motor power | 4.5KW/4.5KW | |

| Power of the lifting motor for the pallet | 2.0KW | |

| Power Of Wire Cuter Motor | 2.0KW | |

| Left and right translation motor power | 2.0KW | |

| Maximum wire feeding speed | 40m/min | |

| 300mm±0.1mm | ||

| Angle accuracy | 90°±0.1mm | |

| Input Power | 380V/50Hz/3Ph | |

| Machine Size(L*W*H) | 3800KG | |

| Machine Size(L*W*H) | 4420mm*1900mm*2100mm | |

| Automatic feeder | Maximum load Weight: | 1500KG |

| Size (L*W*H) | 2100mm*2100mm*1300mm | |

Characteristic description

Wide Processing Range: Supports 4–12mm wire diameters, including carbon steel, stainless steel, and alloy wires.

High Precision: Equipped with servo motor control, ensuring bending accuracy within ±0.1mm.

3D Forming Capability: Capable of producing complex multi-angle and multi-plane wire structures.

User-Friendly Control: Touchscreen CNC interface with multi-language support for easy operation.

Efficient Production: High-speed rotary feeding structure for continuous and stable operation.

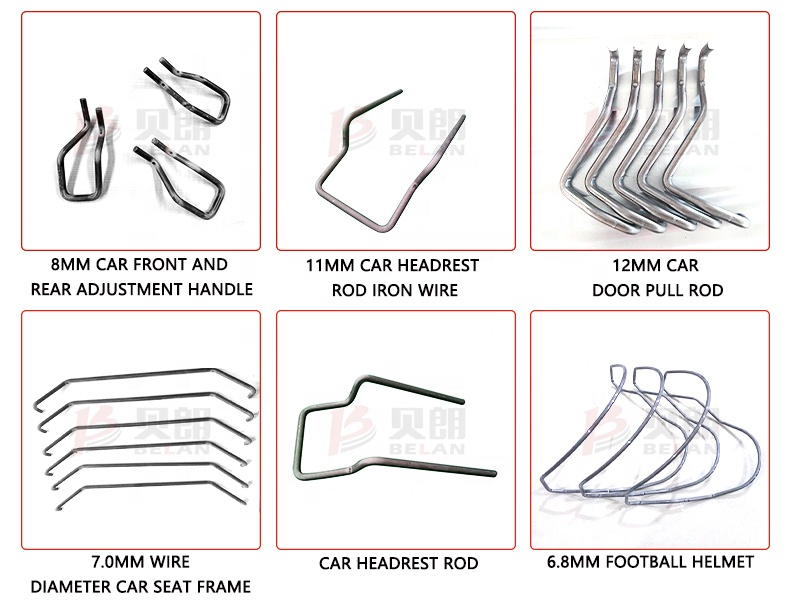

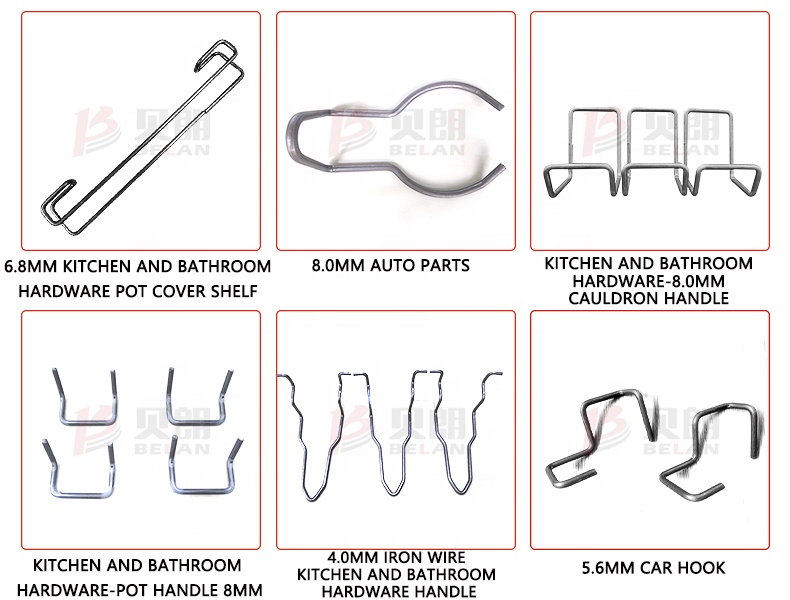

Sample image display

The BL-3D-81200 is widely used in:

Automotive seat frames and structural parts

Wire mesh, racks, and storage systems

Metal furniture and hardware accessories

Industrial wire forming components