parameter

| Applicable Wire Dia. | Soft material Φ:1.6-3.5mm Hard material Φ:1.6-2.5mm |

| Bending stroke | 100~400mm |

| No. of Axis | 12 Axis |

| Total power | 12.4KW |

| Power of Wire Feeding Motor | 2.7KW |

| Power of Crank Arm Motor | 1.0KW*4 |

| Power of Free Hand Motor | 0.4KW |

| Power of Curl Motor | 0.4KW |

| Power of Core Bending Motor | 1.0KW |

| Power of Angle Folding Motor | 0.4KW |

| Power of Angle Folding Lifting Motor | 1.0KW |

| Power of Clamping Motor | 1.5KW |

| Power of Rotating Motor | 1.0KW |

| Input Power | 3AC 380V/50HZ |

| Weight of Machine | 1800KG |

| Size (L*W*H) | 2900mm*1800mm*1700mm |

| Maximum load weight of automatic wire feeder: | 200KG |

characteristic

The double head rotary wire forming machine is a specialized equipment for metal wire forming, which has some unique characteristics and advantages. The following are some main features of the double head rotary wire forming machine:

Efficient production: The double head rotary wire forming machine has two forming heads, and both ends simultaneously shape the wire, thus greatly improving production efficiency.

Highly automated: This type of machine usually has highly automated production capabilities, which can achieve automated production, reduce manual operations, and improve production efficiency.

Versatility: The double head rotary wire forming machine can achieve various forming and processing operations for metal wires by replacing different molds, suitable for wires of different shapes and sizes.

High precision and repeatability: The double head rotary wire forming machine is equipped with a precision CNC system and sensors, which can achieve high-precision forming and ensure the quality and accuracy of the finished product.

Strong adaptability: suitable for different diameters and materials. Strong adaptability: suitable for wires of different diameters and materials, providing flexible processing solutions and a wide range of applications.

Overall, the double head rotary wire forming machine has important characteristics in the field of metal wire forming and processing, providing efficient and accurate processing solutions for various engineering projects, and is widely used in various industries such as manufacturing, electronics, and automobiles.

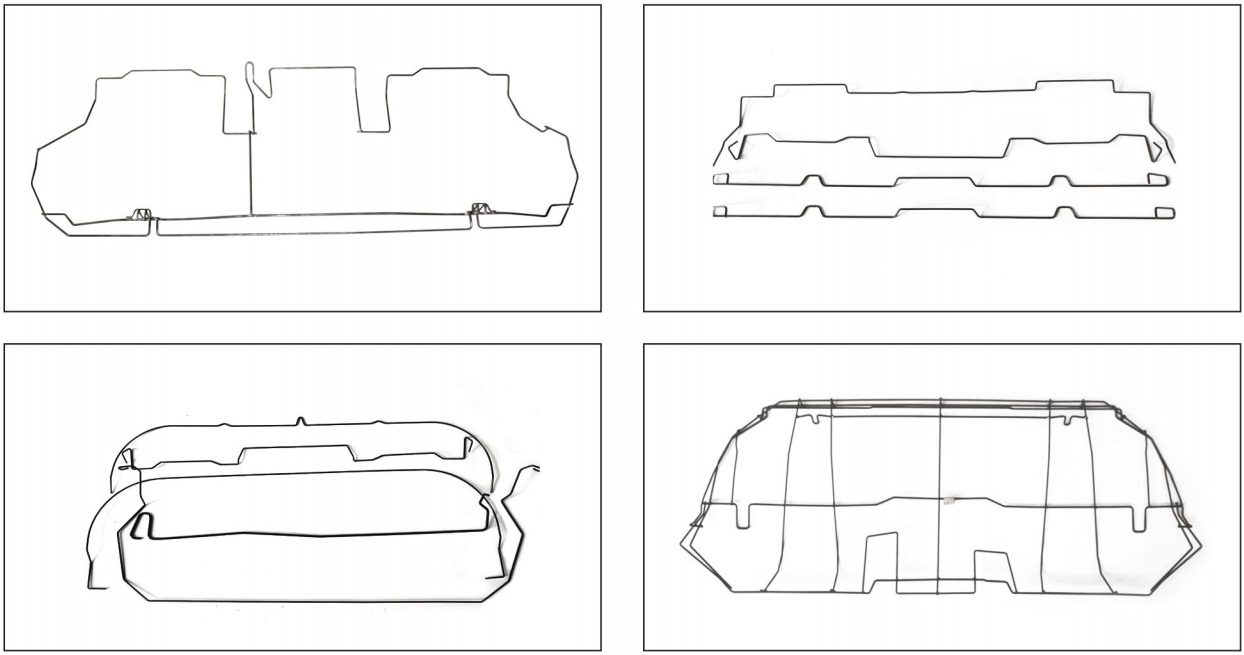

Template