Specification parameters

| Type | BL-TP-30-5E Parameter |

| Applicable Wire Dia. | width Φ:2.0-5.0mm thickness Φ:5.0-30mm |

| Number of control Axis | 13 Axis |

| Total power | 27.7KW |

| Crawler feeding | 1PC |

| Power of wire feeding motor | 4.5KW |

| Power Of wire turning Motor | 2.7KW |

| Servo shear motor motor | 1.0KW |

| Power Of Arm Motor | 2.0KW*8 |

| Power Of Curl Motor | 1.5*1+2.0KW |

| Angle accuracy | 90°±0.2° |

| Input Power | 380V/50Hz/3Ph |

| Weight | 4800KG |

| Maximum load weight of automatic wire feeder: | 1000KG |

| Machine Size(L*W*H) | 2800*2100*2000mm |

| Site occupation: | length 6800mm * width 2500mm |

Characteristic description

Copper aluminum bar bending machine is a specialized equipment used for processing copper and aluminum bars, mainly used to bend copper and aluminum bars into the required shape to meet specific engineering needs. The following are the main uses of the copper aluminum bar bending machine:

Electrical equipment manufacturing: Copper aluminum bars are commonly used conductive materials in electrical equipment, such as distribution cabinets, switchgear, control cabinets, etc. The bending machine can bend copper and aluminum bars into various shapes to meet the structural and connection requirements of different equipment.

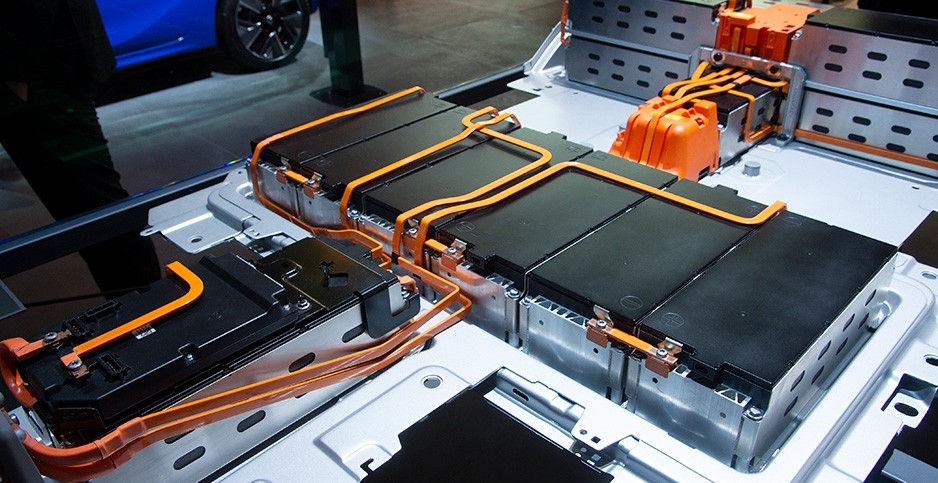

Power engineering: In the power industry, copper and aluminum bars are widely used in transmission and distribution systems. Bending machines can process copper and aluminum bars into connectors, conductive slots, and other components to ensure the efficiency and safety of power transmission.

New energy industry: In new energy industries such as solar and wind energy, copper and aluminum bars are also commonly used conductive materials. Bending machines can be used to make solar panel components, conductive components of wind power generation equipment, etc.

Elevator manufacturing: In the elevator manufacturing process, copper and aluminum bars are used in the electrical control system of the elevator, and the bending machine can process the copper and aluminum bars into connectors that conform to the elevator structure.

Industrial machinery: In various industrial equipment and machinery, copper and aluminum bars also play an important conductive role, and bending machines can be customized to the desired shape to adapt to the electrical connections of different machinery.

Overall, the copper aluminum strip bending machine plays an important role in the fields of electrical, electrical, and new energy, providing efficient and accurate copper aluminum strip processing solutions for various engineering projects.

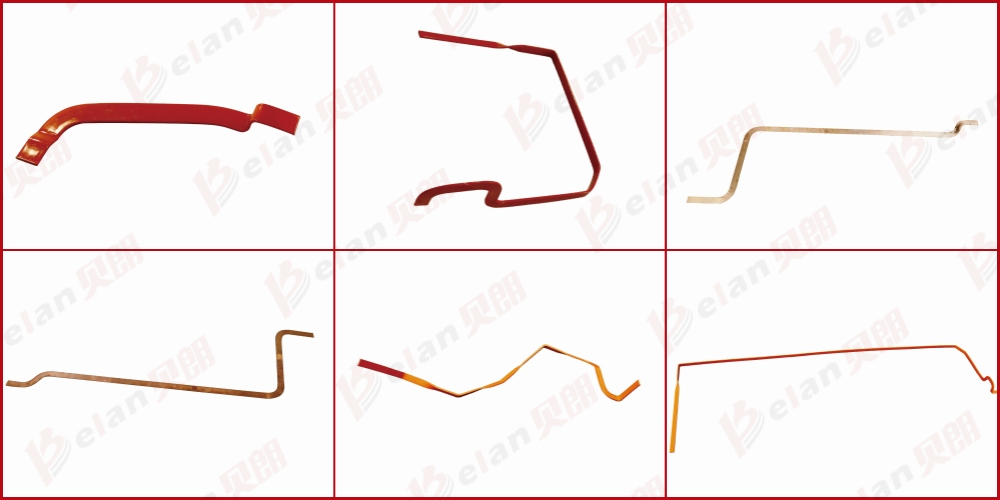

Sample image display