Specification parameters

| Type | BL-3D-10300 Parameter |

| Applicable Wire Dia. | Soft material Φ:1.0mm-4.0mm Hard material Φ:1.0mm-2.5mm |

| Number of control Axis | 10 Axis |

| Total power | 9.75KW |

| 1 axis arm | 0.75KW |

| 2 axis arm | 0.75KW |

| 3 axis arm | 0.75KW |

| 4 axis arm | 0.75KW |

| 5 axis left and right hand | 0.4KW |

| 6 axis curl | 0.4KW |

| 7 axis feed | 1.8KW |

| 8 axis turntable | 3.0KW |

| 9 axis bending core | 0.4KW |

| 10 axis peeling machine | 0.75KW |

| Maximum wire feeding speed | 80M/min |

| Wire feeding accuracy | 300mm±0.1mm |

| Input Power | 380V/50Hz/3Ph |

Characteristic description

A Copper Wire Peeling, Peeling, and Bending Machine is a specialized piece of equipment used in industries that work with copper wire. This machine offers several advantages due to its ability to process copper wire in multiple ways. Here are some of the key advantages:

Multi-Function Capability:

Combining wire peeling, peeling, and bending functions in a single machine provides a comprehensive solution for processing copper wire efficiently and effectively.

Material Efficiency:

The wire peeling function removes the outer layer of the copper wire, allowing for the recovery of high-quality material. This can lead to cost savings and reduced waste.

High Precision:

These CNC copper wire inductance coil paint removal molding bending machines are designed with precision engineering to ensure accurate peeling and bending. This is crucial for industries that require consistent and precise wire processing.

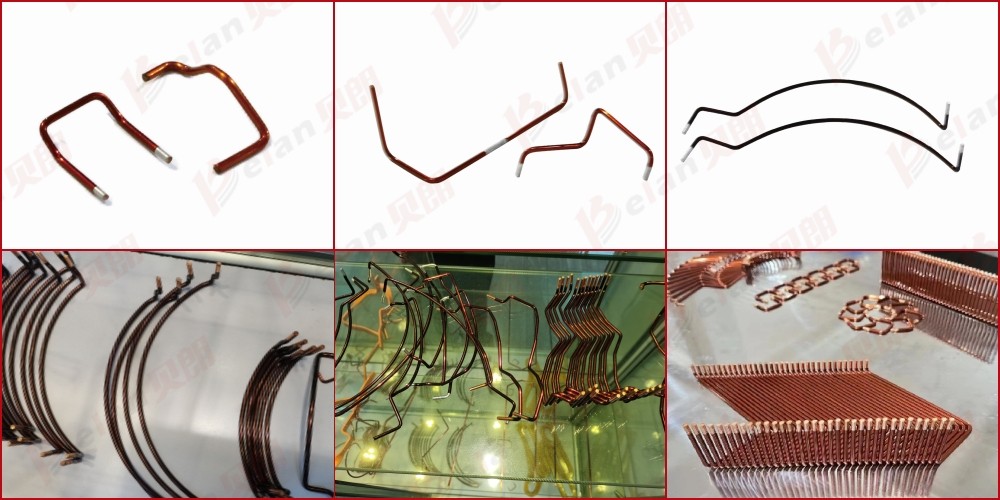

Sample image display