Specification parameters

| Type | BL-2T-12250 Parameter |

| Applicable Wire Dia. | Soft material Φ:1.6-3.5mm Hard material Φ:1.6-2.5mm |

| Bending stroke | 100~400mm |

| No. of Axis | 12 Axis |

| Total power | 12.4KW |

| Power of Wire Feeding Motor | 2.7KW |

| Power of Crank Arm Motor | 1.0KW*4 |

| Power of Free Hand Motor | 0.4KW |

| Power of Curl Motor | 0.4KW |

| Power of Core Bending Motor | 1.0KW |

| Power of Angle Folding Motor | 0.4KW |

| Power of Angle Folding Lifting Motor | 1.0KW |

| Power of Clamping Motor | 1.5KW |

| Power of Rotating Motor | 1.0KW |

| Input Power | 3AC 380V/50HZ |

| Weight of Machine | 1800KG |

| Size (L*W*H) | 2900mm*1800mm*1700mm |

| Maximum load weight of automatic wire feeder: | 200KG |

Characteristic description

Cost-Efficiency:

By doubling the output in a single operation, double-head 3D wire car seat bending machine can be more cost-effective in terms of labor and time compared to using multiple single-head machines.

High Precision and Accuracy:

These machines are designed with precision engineering to ensure that both bending heads produce wire forms with tight tolerances and high accuracy. This is crucial for industries that require consistent and precise wire forms.

Versatility in Wire Diameter and Material:

Double end wire bending machines are typically capable of handling a wide range of wire diameters and materials, providing versatility for various applications.

Reduced Setup Time:

Modern double end wire bending machines often come equipped with advanced computer numerical control (CNC) systems. These systems allow for quick and easy programming and setup, reducing the time it takes to switch between different wire-forming jobs.

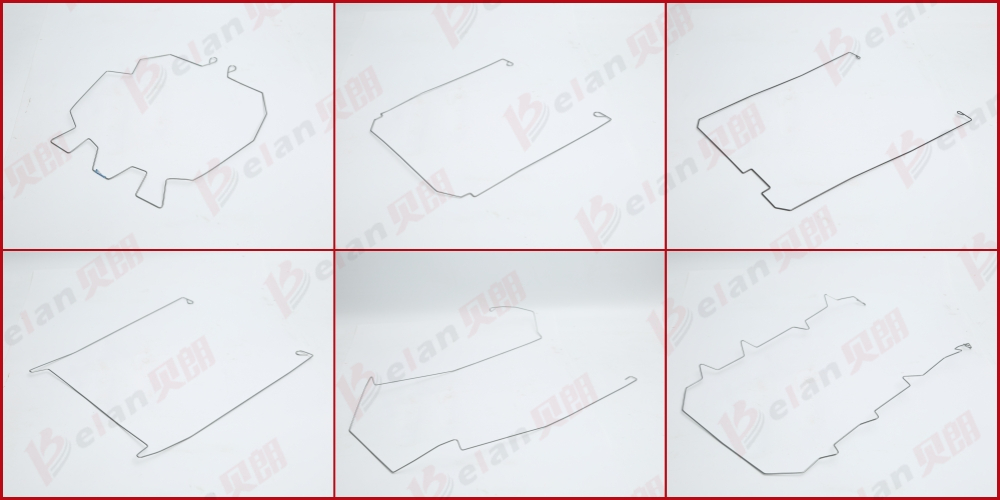

Sample image display

Dedicated equipment for bending foam steel wire for automotive rear frame, specializing in bending small wire diameters, and suitable for metal wire bending in other industries

Factory Realistic View