Specification parameters

| Type | BL-2T-16600 Parameter |

| Applicable Wire Dia. | Soft material Φ:3.0-6.0mm Hard material Φ:3.0-4.5mm |

| No. of Axis | 16 Axis |

| Total power | 16.6KW |

| Power of Wire Feeding Motor | 2.7KW |

| (left/right) Power of Turning Motor | 2.7KW |

| (left/right) Angle motor power | 1.0KW |

| (left/right) Inner roll motor power | 1.0KW |

| (left/right) Lift motor power | 1.0KW |

| (left/right) I/O motor power | 2.7KW |

| (left/right) Wire Clamp motor power | 1.0KW |

| Power of Wire Cuter Motor | 1.0KW |

| Power of Rotating& Straighten Motor | 2.0KW |

| Power of Moving Motor | 1.5KW |

| Input Power | 3AC 380V/50HZ |

| Weight of Machine | 5500KG |

| Size (L*W*H) | 8000mm*1500mm *1600mm |

| Maximum load weight of automatic wire feeder: | 1000KG |

Characteristic description

Versatility in Wire Diameter and Material:

Double end wire bending machines are typically capable of handling a wide range of wire diameters and materials, providing versatility for various applications.

Reduced Setup Time:

Modern Double-head car seat steel wire forming machine often come equipped with advanced computer numerical control (CNC) systems. These systems allow for quick and easy programming and setup, reducing the time it takes to switch between different wire-forming jobs.

Complex Geometries:

With multiple bending heads, these machines can create wire forms with complex shapes and angles that would be challenging or impossible to achieve with single-head machines.

Consistency and Quality Control:

The automated nature of double end wire bending machines ensures a high level of consistency in the produced wire forms. This consistency is crucial for industries where quality control is a top priority.

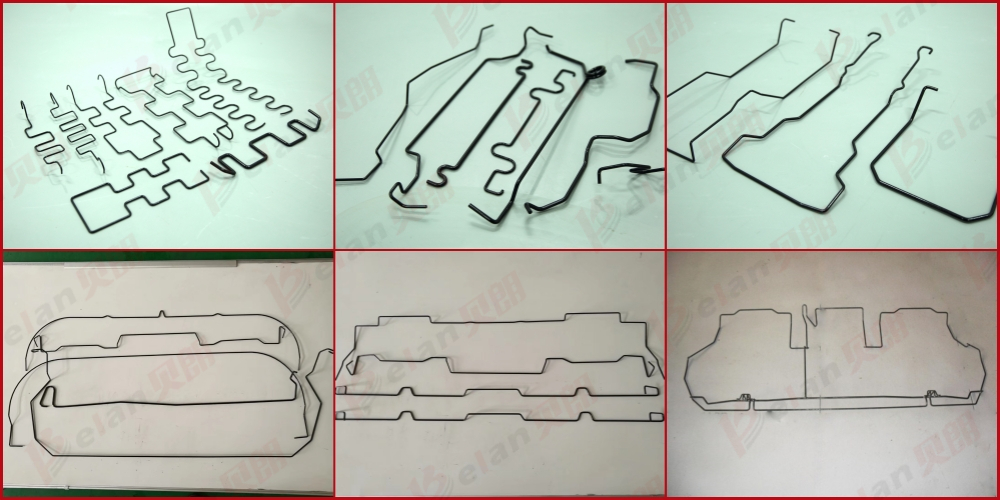

Sample image display