Specification parameters

| Type | Grid machine Parameter |

| Applicable Wire Dia. | W-shaped steel wire:Φ2.0mm Plastic wrapped steel wire:Φ3.0mm |

| Number of control Axis | 28-34Axis |

| Total power | 30KW |

| Weaving station | 10 Axis |

| W Forming Station | 2-4Axis |

| Plastic wrapped steel wire station | 12 Axis |

| Sheep Horn Hook Forming Station 1 | 2-4Axis |

| Sheep Horn Hook Forming Station 2 | 2-4Axis |

| Rough stock of process data | ≥2000 |

| Stabilized power (reference) | 40kw |

| Pneumatic system | 0.5-0.6MPa |

| probe | 4 pc |

| Input Power | 380V/50Hz/3Ph |

| Weight | 6000KG |

| Machine Size(L*W*H) | 11500*4500*2400mm |

Feature and Function

The car seat frame grid machine is a specialized equipment used for manufacturing car seat frames. The car seat frame is the supporting structure of the seat, usually made of metal material, used to fix the seat cushion and provide support.

The following are some characteristics and advantages of the car seat frame grid machine:

Automated production: This equipment usually has a highly automated production capacity, which can automatically complete the manufacturing process of seat frames, thereby improving production efficiency.

Accurate forming ability: The car seat frame grid machine adopts advanced CNC technology, which can achieve precise forming of metal materials, ensuring the quality and accuracy of the frame.

Multi station design: Usually with multi station design, multiple processes can be carried out on the same equipment, thereby accelerating production pace.

Strong adaptability: It can be customized for different models of seat frames to meet the needs of different car models.

Efficient and energy-saving: Through automated production and precise molding, waste generation can be reduced, energy consumption can be reduced, and the effect of efficient and energy-saving can be achieved.

Stability and reliability: The structural design and manufacturing quality of automotive seat frame grid machines are usually very stable and reliable, which can ensure long-term stable operation and reduce equipment failures and maintenance time.

Improving production efficiency: Due to its highly automated characteristics, the car seat frame grid machine can significantly improve production efficiency and reduce labor costs.

Overall, the automotive seat frame grid machine is an important equipment in the manufacturing process of automotive seats. It can provide efficient and accurate seat frame manufacturing solutions for automotive manufacturers, thereby ensuring the quality and safety of automotive seats.

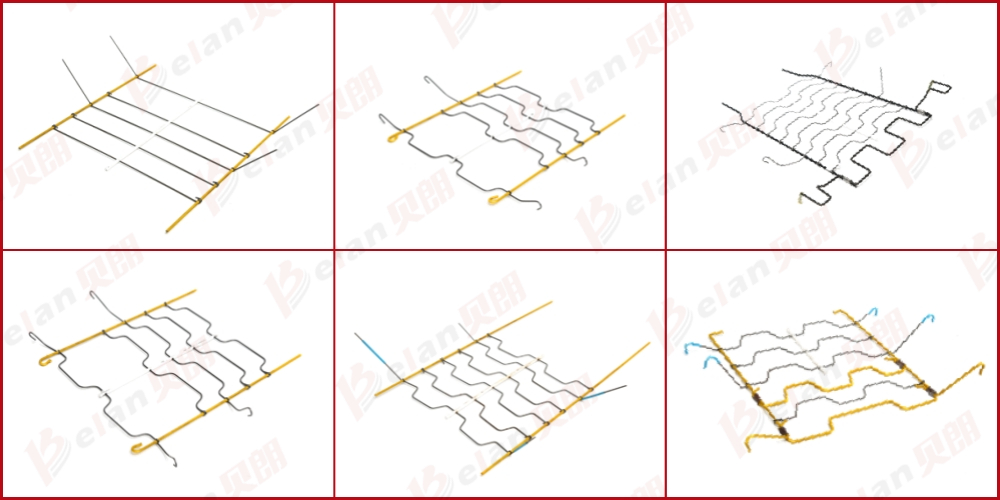

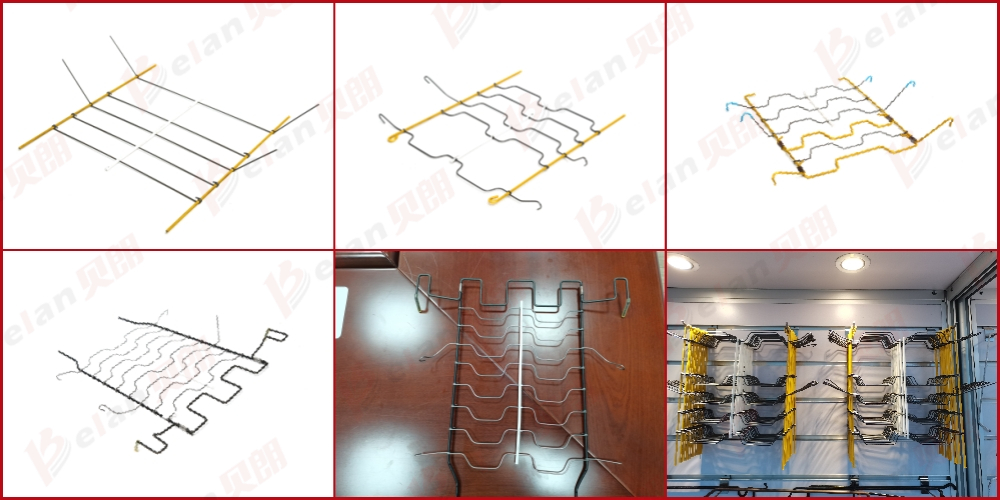

Product samples