As European manufacturers push for higher automation and cost efficiency, more companies are shifting from expensive local machinery to high-value Chinese solutions. BELAN Automation recently delivered a customized copper & aluminum busbar processing equipment line to LEONI Group, a global leader in automotive wiring systems.

01 LEONI Group: A Leading Wiring System Manufacturer

LEONI, headquartered in Germany, is known for its strict quality standards and advanced production systems. Increasing supply chain pressure and rising equipment costs have led the company to evaluate Chinese automation solutions. After multiple rounds of comparison, LEONI selected BELAN for its stable performance and strong customization capabilities.

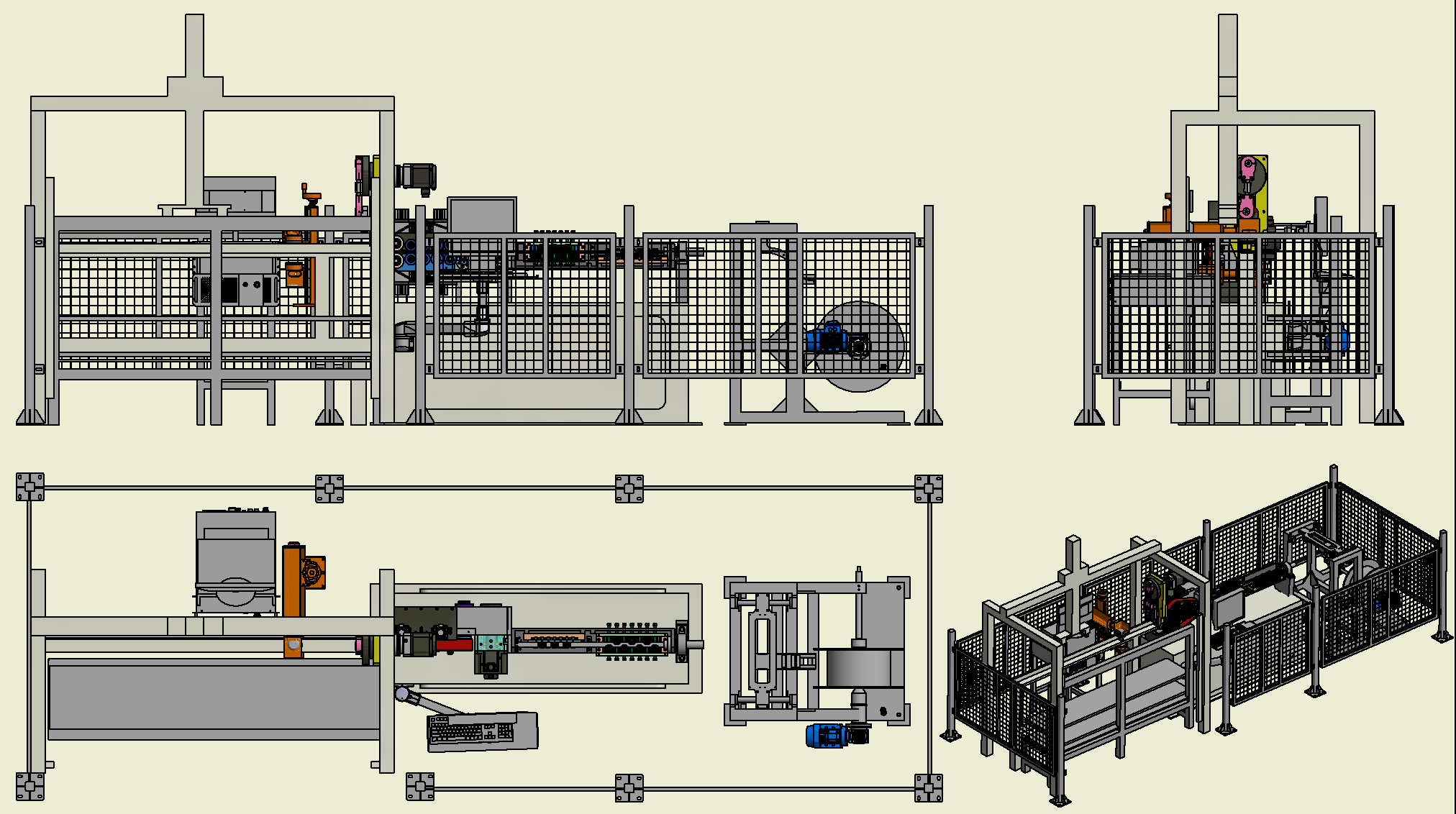

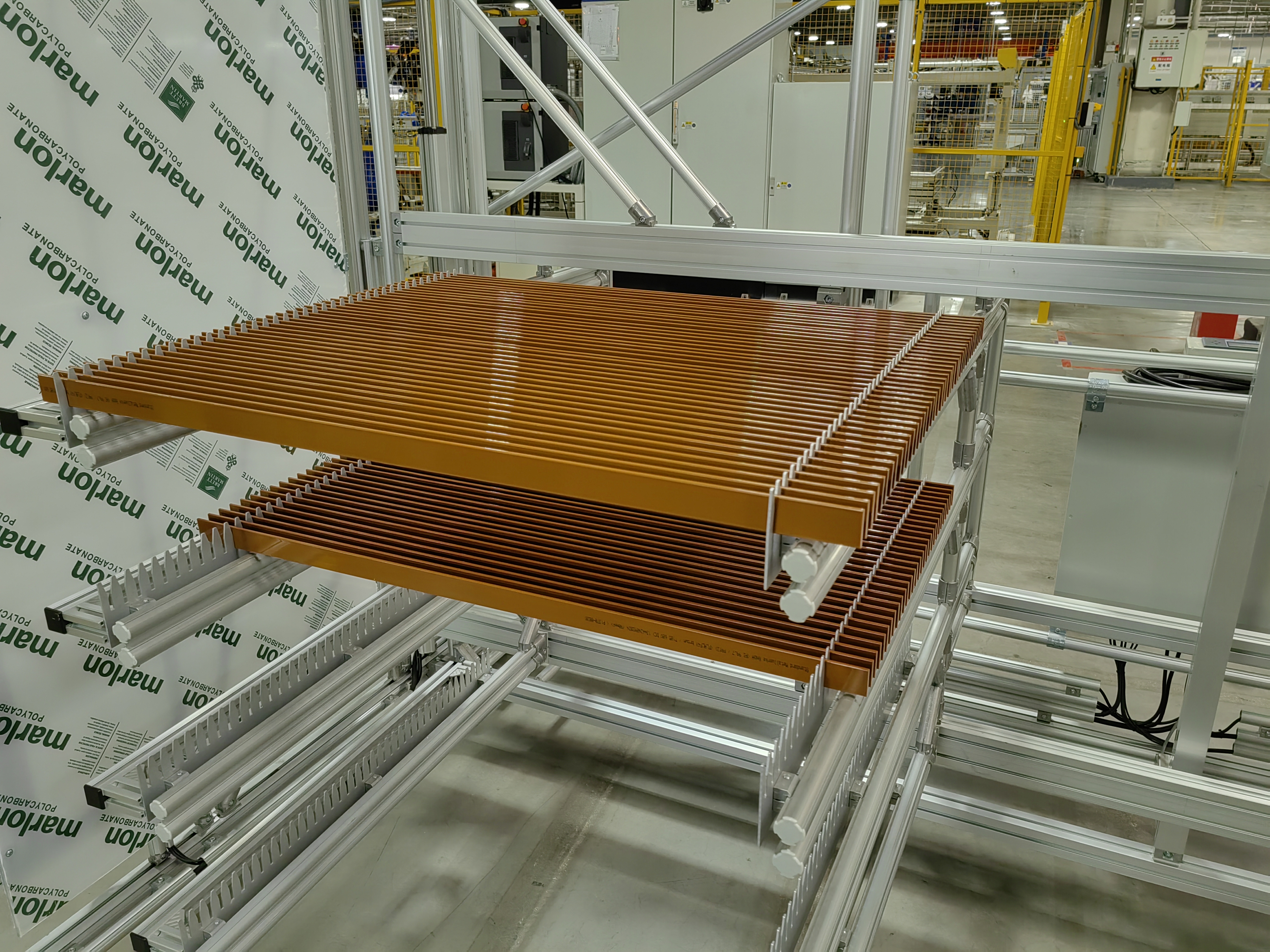

02 Custom Copper & Aluminum Busbar Processing Solution

BELAN designed a tailored non-standard automation system including:

Automatic busbar loading

High-precision straightening

Servo-controlled cutting

Laser data code marking connected to MES

Intelligent sorting and unloading

The solution ensures stable, accurate and efficient mass production.

03 One-Month On-Site Installation and Training

A BELAN engineering team stayed on-site for one month to complete installation, calibration, MES integration, debugging, operator training and trial production verification. The equipment passed stability tests and met LEONI’s acceptance requirements.

04 Why More European Companies Choose Chinese Equipment

During the project, LEONI emphasized: “We choose Chinese equipment not only for lower cost, but for higher overall value and faster customization.” This reflects a broader trend of European manufacturers adopting Chinese automation solutions.

05 Conclusion

The successful delivery of this copper & aluminum busbar processing equipment demonstrates BELAN’s technical strength and growing global competitiveness. BELAN will continue providing smart, reliable solutions for international customers.