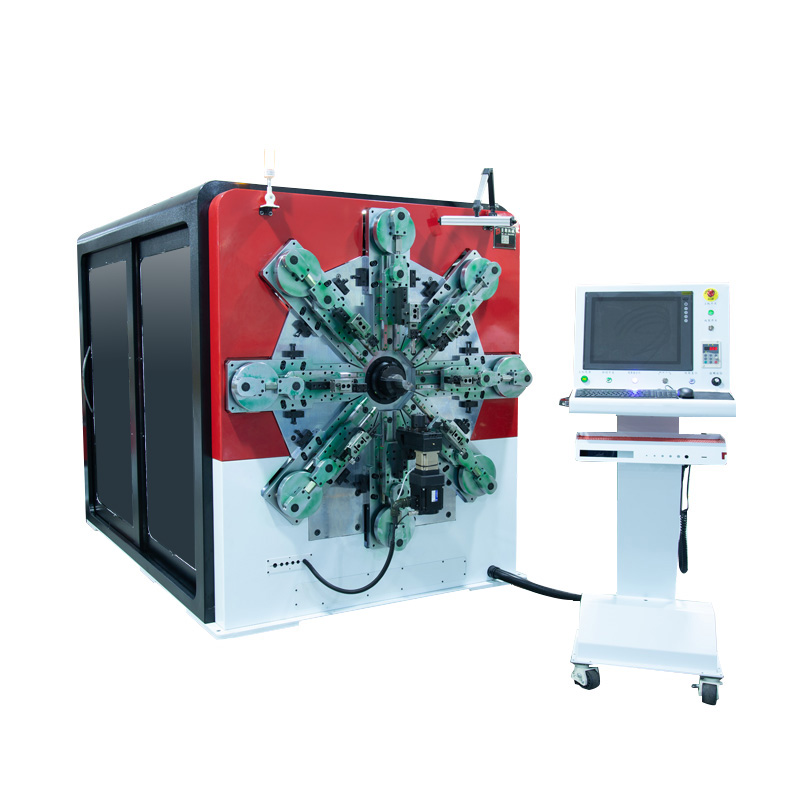

With the increasing demand for high-precision steel wire parts in the automotive parts manufacturing industry, it is particularly important to choose a suitable wire bending equipment. The rotary 3D wire bending machine launched by our factory has won high recognition in the market for its high precision, compact and flexible structure. Especially on the day before the Spring Festival holiday, we completed the shipment of the last batch of equipment, meeting the urgent needs of our customers and demonstrating our professional and efficient service capabilities.

Overview of Equipment Advantages

Wide range of bending wire diameter: supports precise bending of 3-8mm wire diameter, covering the manufacturing needs of most automotive steel wire parts.

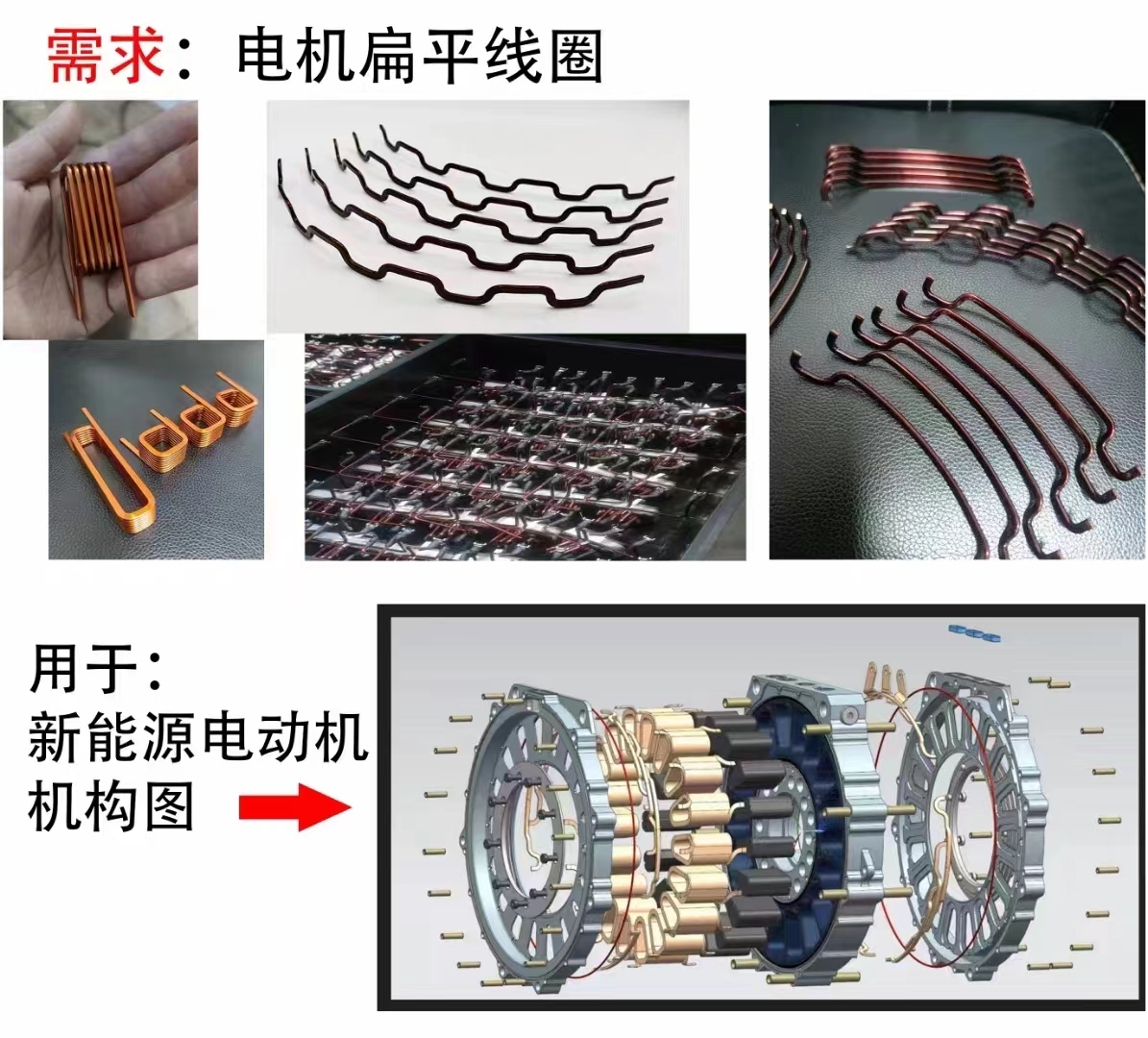

Innovative turning head structure: The unique turning head design enables the equipment to perform excellently in complex bending processes, especially suitable for multi angle and multi plane wire forming.

High precision control: adopting advanced CNC technology, high bending accuracy, reducing waste loss, and improving production efficiency.

Compact and flexible: The device occupies a small area, suitable for small and medium-sized workshops, and is also easy to integrate with the entire production line.

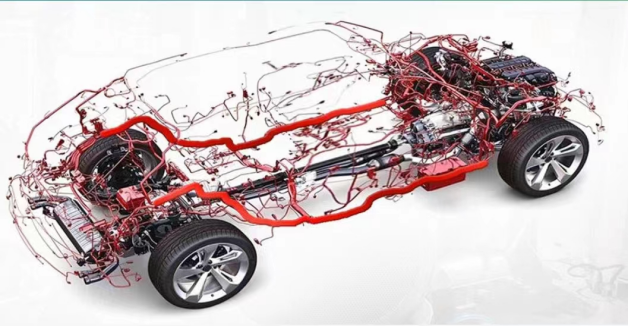

application area

Automotive components: such as seat frames, engine mounts, exhaust system supports, etc.

Industrial springs and steel wire components: meet the high-precision steel wire forming needs of other industrial fields.

The last batch of shipments before the Spring Festival

Before the Spring Festival holiday, our team worked tirelessly to complete the production, quality inspection, and packaging processes, ensuring that the last batch of rotary 3D wire bending machines were delivered to customers on time. This batch of equipment is not only a quick response to customer needs, but also reflects our responsibility and commitment as a professional CNC equipment manufacturer.

Why choose us?

Industry leading: years of focus on research and manufacturing of wire bending equipment, mature technology, and stable performance.

Global service: covering multiple markets, providing fast pre-sales consultation and after-sales support.

Customized solution: Provide equipment customization services according to customer needs to meet personalized production requirements.

The Spring Festival holiday is approaching, but we still welcome the challenges of the new year with full enthusiasm. If you are interested in the rotary 3D wire bending machine or have equipment requirements, please feel free to contact us at any time. We look forward to working together with more customers to create brilliance!