Specification parameters

| Type | BL-TP-45-6E Parameter |

| Applicable Wire Dia. | width :2.0-6.0mm |

| thickness :10.0-45mm | |

| Number of control Axis | 13Axis |

| Total power | 37.7KW |

| Crawler feeding | 1PC |

| Power of wire feeding motor | 4.5KW |

| Power Of wire rotation Motor | 2.7KW |

| Power Of 1 Coling Motor | 2.0KW*1 |

| Power Of 2 Coling Motor | 4.5kw*1 |

| Power Of Arm Servo Motor | 2.0KW*6 |

| Power Of Arm Servo Motor | 5.5KW*2 |

| Power Of Cutting Servo Motor | 1.0KW |

| Angle accuracy | 90°±0.2° |

| Input Power | 380V/50Hz/3Ph |

| Weight | 6000KG |

| Maximum load weight of automatic wire feeder: | 1000KG |

| Machine Size(L*W*H) | 2800*2200*2100mm |

| Site occupation: | length 6800mm * width 2500mm |

Characteristic description

Copper bar bending machine is a mechanical equipment specifically used for processing copper bars (including aluminum bars), which has the following characteristics:

1.Multifunctionality: Copper bar bending machines typically have multiple bending tools and molds, which can achieve bending operations of different shapes and angles to meet the needs of various engineering projects.

2.Stability and reliability: The structural design and manufacturing quality of copper bar bending machines are usually very stable and reliable, which can ensure long-term stable operation and reduce equipment failures and maintenance time.

3.Safety: Modern copper bar bending machines are usually equipped with various safety measures, such as emergency stop buttons, safety protective covers, etc., to ensure the safety of operators.

4.Flexibility: Copper bar bending machines usually have a certain degree of flexibility, which can adapt to different specifications, sizes, and shapes of copper bars, providing customized processing solutions.

Energy conservation and environmental protection: Modern copper bar bending machines usually use advanced energy-saving technology to reduce energy consumption and meet environmental requirements.

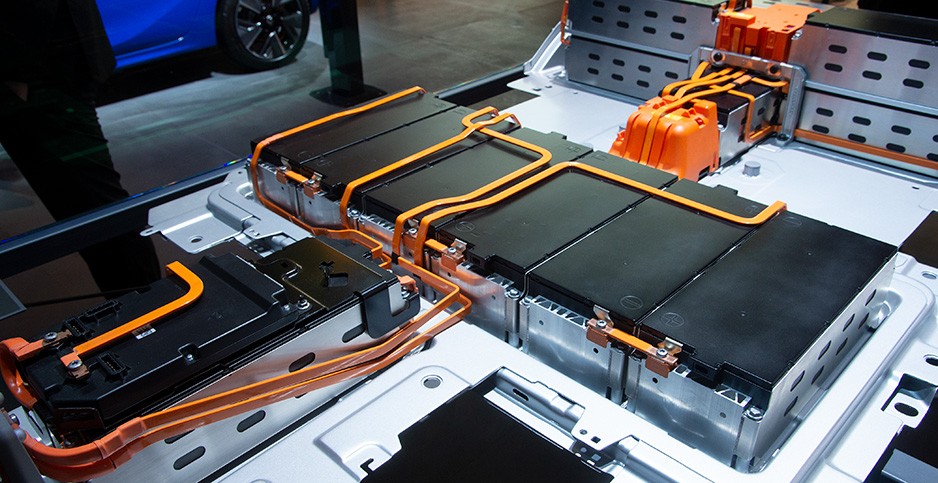

Overall, the copper bar bending machine is an efficient, accurate, and safe processing equipment widely used in fields such as electrical, power, and new energy, providing reliable copper bar processing solutions for various engineering projects

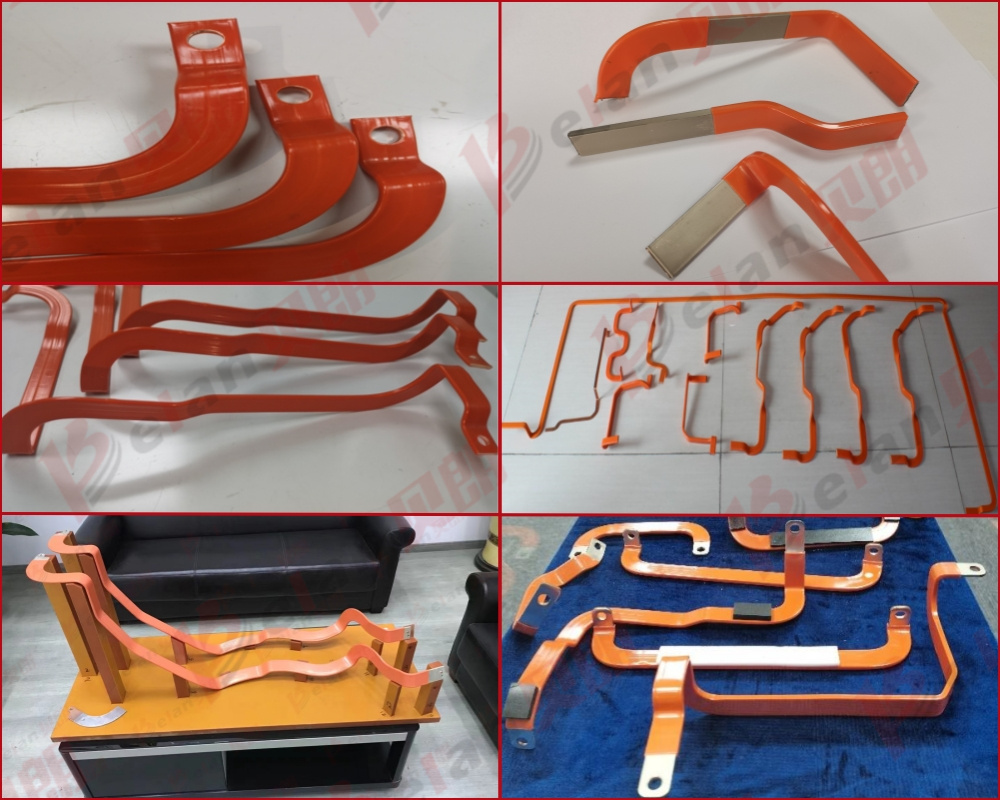

Sample image display

Copper bar bending machine (maximum processing range of copper and aluminum bars: 45mm * 2mm) is a multifunctional special machine that integrates all the functions of 3D bending machine and spring machine. This machine adopts a unique camless and rocker free design, and is independently controlled by multiple sets of servo motors. The Belan copper bar bending machine is widely used for forming conductive bars, new energy battery connection bars, new energy battery modules, copper busbar forming, hard busbar forming, conductive bars, battery connection bars, copper bars Bare row forming, etc. Precise and accurate, fast machine adjustment, stable and reliable.