Specification parameters

| Type | BL-TP-45-6E Parameter |

| Applicable Wire Dia. | width :Φ2.0-8.0mm thickness :Φ8.0-45mm |

| Number of control Axis | 13 Axis |

| Total power | 35.2KW |

| Crawler feeding | 1PC |

| Power of wire feeding motor | 4.5KW |

| Power Of wire turning Motor | 2.7KW |

| Servo shear motor motor | 1.0KW |

| Power Of Arm Motor | 2.0KW*6 |

| Power Of Arm Motor | 5.5KW*2 |

| Power Of Curl Motor | 2.0KW*2 |

| Input Power | 380V/50Hz/3Ph |

| Weight | 3800KG |

| Maximum load weight of automatic wire feeder: | 1000KG |

| Machine Size(L*W*H) | 2800*2200*2100mm |

| Site occupation: | length 6800mm * width 3500mm |

Characteristic description

Versatility and Customization:

Some advanced models may offer the capability to perform multiple types of bends, including simple angles, U-bends, and complex shapes, allowing for a wide range of applications.

Mobility and Portability:

Depending on the specific aluminum wire forming machine and its intended use, it may be designed for stationary operation within a workshop or have features that allow for mobility and easy relocation.

Maintenance and Serviceability:

A well-designed copper bar bending machine will have provisions for easy maintenance, with access points for lubrication, adjustments, and replacement of worn components.

Copper bar bending machines play a crucial role in the electrical industry, enabling the fabrication of precisely shaped copper components that are essential for efficient electrical systems. They come in various sizes and configurations to suit different production needs and can greatly enhance the efficiency and accuracy of copper bar processing.

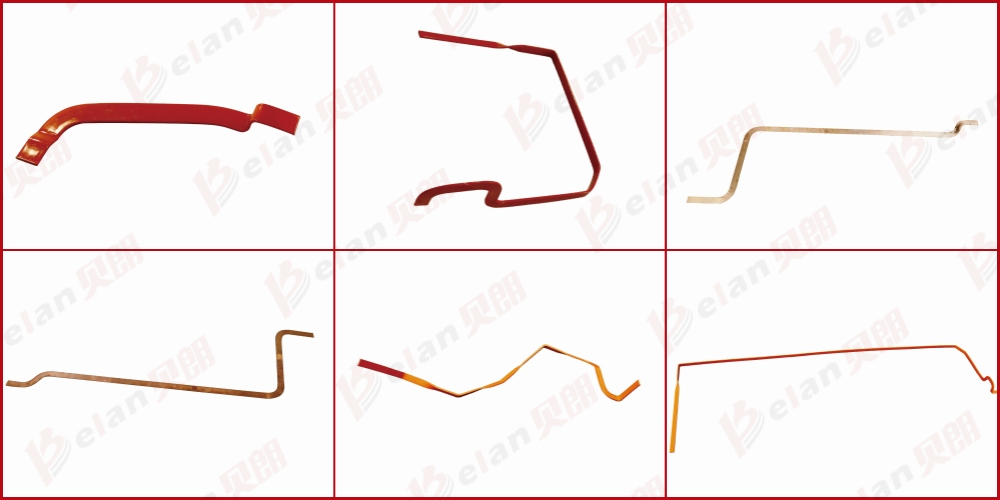

Sample image display

Copper busbar bending machine (maximum processing range of copper and aluminum bars: 45mm * 2mm) is a multifunctional special machine that integrates all the functions of 3D bending machine and spring machine. This machine adopts a unique camless and rocker free design, and is independently controlled by multiple sets of servo motors. The Belang copper bar bending machine is widely used for forming conductive bars, new energy battery connection bars, new energy battery modules, copper busbar forming, hard busbar forming, conductive bars, battery connection bars, copper bars Bare row forming, etc. Precise and accurate, fast machine adjustment, stable and reliable.