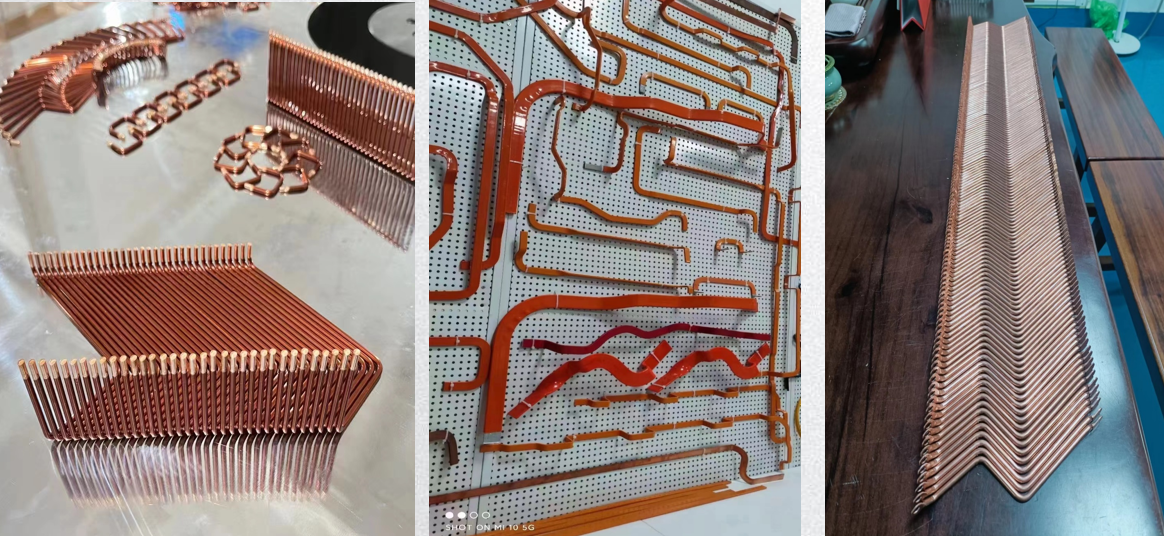

| Type | BL-TP-45-6E Parameter |

| Applicable Wire Dia. | width Φ:2.0-8.0mm thickness Φ:8.0-45mm |

| Number of control Axis | 13 Axis |

| Total power | 35.2KW |

| Crawler feeding | 1PC |

| Power of wire feeding motor | 4.5KW |

| Power Of wire turning Motor | 2.7KW |

| Servo shear motor motor | 1.0KW |

| Power Of Arm Motor | 2.0KW*6 |

| Power Of Arm Motor | 5.5KW*2 |

| Power Of Curl Motor | 2.0KW*2 |

| Input Power | 380V/50Hz/3Ph |

| Weight | 3800KG |

| Maximum load weight of automatic wire feeder: | 1000KG |

| Machine Size(L*W*H) | 2800*2200*2100mm |

| Site occupation: | length 6800mm * width 3500mm |

Safety Features:

Safety is a critical aspect of any industrial machine. Copper bar bending machines may include features like emergency stop buttons, safety guards, and sensors to ensure the well-being of operators.

Measurement and Calibration:

Many machines have measurement systems to ensure accurate and consistent bends. This can include scales, digital readouts, or laser-guided systems for precise bending angles.

Hydraulic or Mechanical Operation:

Copper bar bending machines can operate using either hydraulic or mechanical systems. Hydraulic systems use fluid pressure to exert force, while mechanical systems use gears, cams, and linkages to achieve bending.

Bending Capacity:

The machine's specifications will indicate its maximum bending capacity in terms of the size and thickness of copper bars it can handle.