Specification parameters

| Type | BL-3D-51400Parameter | |

| Applicable Wire Dia. | Soft material Φ:5.0-14.0mm Hard material Φ:5.0-10.0mm | |

| Bending stroke | 650mm | |

| Number of control Axis | 5 Axis | |

| Total power | 19.4KW | |

| Power Of Roating arm Motor | 4.4KW | |

| Power of wire feeding motor | 7.5KW | |

| Angle motor power | 5.0KW | |

| Lifting motor power | 1.0KW | |

| Power Of wire cutting Motor | 1.5KW | |

| Internal rotation motor power | / | |

| Maximum wire feeding speed | 50M/min | |

| Wire feeding accuracy | 300mm±0.1mm | |

| Angle accuracy | 90°±0.2° | |

| Input Power | 380V/50Hz/3Ph | |

| Weight | 4600kg | |

| Machine Size(L*W*H) | 3800×2200×2000mm | |

| Automatic feeder | Maximum load Weight: | 2000KG |

| Diameter of Round Tray | φ2000mm | |

| Input Power | 2.2KW | |

| Weight | 1600Kg | |

| Size (L*W*H) | 2400*2400*1800mm | |

Characteristic description

1. Intuitive structure and efficient operation

The three-dimensional forming is realized by turning the head, the structure is very intuitive, the stability of the wire feeding is guaranteed, and it is very convenient to modify wherever it needs to be modified in operation.

2. Five-axis servo intelligent and efficient

Servo turning head 3d steel wire bending machine adoption of servo motors imported from Japan, and wire feeding, turning, bending, lifting, and cutting are closely coordinated to produce low-carbon steel wire products of 5-10mm / 5-14.0mm respectively.

3. Any rotor, flexible and efficient

The separation of the rotor and the wire feeding in servo steel wire bending not only ensures the stability of the wire feeding machine, but also ensures the flexibility of molding, especially suitable for the production of small parts.

4. Professional numerical control, precise and efficient

Turning head 3D wire bending machine adopt Guangdong Topcon industrial software control, precise full servo drive, achieve wire feeding 300±0.1mm, knuckle 90 repeat positioning accuracy±0.2.

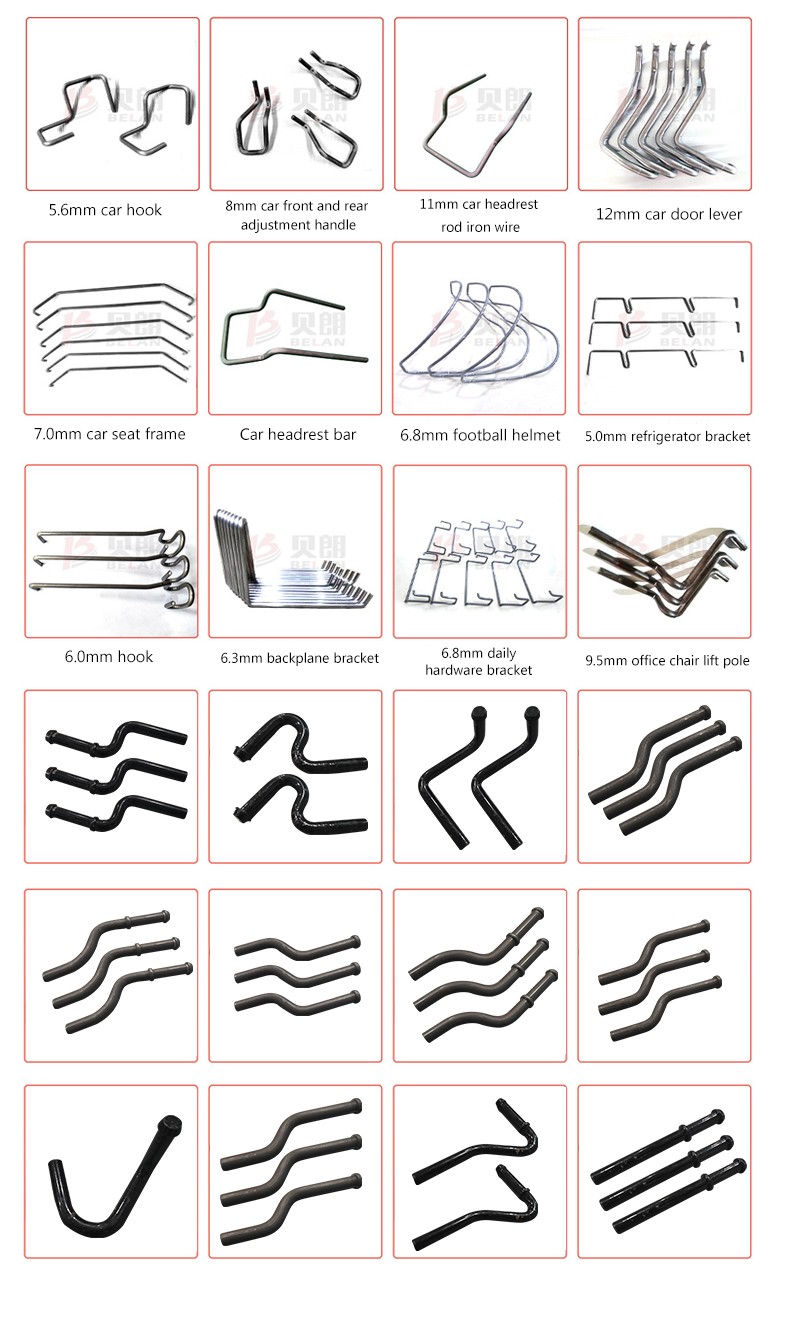

Sample image display

Steel wire bending machine suitable for production: car seat frame, sun visor frame, car door lock lever, metal wire for handicrafts, kitchen utensils and tableware brackets, storage cages, supermarket trolleys, supermarket shelves and other wire forming products.